| "Descrizione" by Ark90 (12431 pt) | 2024-Oct-02 12:11 |

Review Consensus: 10 Rating: 10 Number of users: 1

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

Sodium Laureth sulfate or SLES, is a chemical compound and belongs to a group of salts of sulfated ethoxylated alcohols. It occurs in liquid form or clear transparent slightly yellow gel or white fine powder.

The name describes the structure of the molecule:

- Sodium is the sodium ion (Na+), an alkaline metal.

- Laureth is a term used in the cosmetics industry for a mixture of polyethylene glycol (PEG) and lauryl alcohol. The term 'laureth' is a contraction of 'lauryl ether', where 'lauryl' refers to the 12-carbon lauryl group derived from lauric acid, a medium-chain fatty acid found in coconut oil and palm kernel or palm oil.

- sulphate is a sulphate group (SO4-2-), a sulphur atom bonded to four oxygen atoms and having a negative charge.

The synthesis process takes place in different steps:

- Extraction.The raw materials are lauryl alcohol and ethylene oxide. Lauryl alcohol is typically derived from coconut or palm oil, while ethylene oxide is a petrochemical product.

- Ethoxylation. Lauryl alcohol is reacted with ethylene oxide in a process called ethoxylation. This reaction is catalysed by a base, usually a strong alkali such as potassium hydroxide. The term 'eth' in 'laureth' indicates that ethylene oxide has been added.

- Sulphonation. Ethoxylated alcohol is reacted with sulphur trioxide (SO3) to produce a sulphate.

- Neutralisation. The sulphate is neutralised with sodium hydroxide (NaOH) to produce sodium sulphate.

- Purification. The resulting product is purified through distillation and filtration to remove any unreacted materials and by-products.

- Quality control. The final product is tested to ensure that it meets quality standards.

SLES (Sodium laureth sulfate) must not be confused with SLS because, although both are similar and have sulphuric acid and lauryl alcohol as their formula, differ in chemical properties. In SLES, which is less aggressive than SLS but is ethoxylated (obtained from ethylene oxide), it is not uncommon to find in SLES ethylene oxide and 1,4-dioxane residues, chemical compounds that are considered carcinogenic.

The term 'eth' refers to the ethoxylation reaction with ethylene oxide after which residues of ethylene oxide and 1,4-dioxane, chemical compounds considered carcinogenic, may remain. The degree of safety therefore depends on the degree of purity of the compound obtained. No manufacturer appears to provide this information on the label, at least as of the date of this review.

A preliminary remark must be made about synthetic surfactants, which can be divided into four groups:

- Anionic (SLS, ALS, SLES), which solubilises well with lipid monolayers but not with lipid bilayers model of liposomes or cytotoxicity tests towards cultured skin cells

- Nonionic amphoteric (CAPB), which solubilises well with both mono- and bilayers

- Biotensioactive (SAP), which penetrates monolayers at 1% dry mass without solubilisation, and probably penetrates bilayers, increasing their size (without solubilisation).

What it is for and where

Chemical intermediate, anionic surfactant, densifying and foaming agent, with good solvency, wide compatibility, strong resistance to hard water, high biodegradation and relatively low skin and eye irritation.

Sodium Laureth sulfate is used in cosmetics, in liquid detergents, such as hair and bath shampoos, dishwashing detergents, toothpastes, bubble bath and hand washing, soap etc.. In chromatography as a reagent, it has excellent properties as a solvent. In printing and dyeing industry, oil and leather, textile,,, it can be used as lubricant, dyeing agent, cleaner, foaming agent and degreasing agent.

Cosmetics

Cleansing agent. Ingredient that cleanses skin without exploiting the surface-active properties that produce a lowering of the surface tension of the stratum corneum.

Foaming. Its function is to introduce gas bubbles into the water for a purely aesthetic factor, which does not affect the cleaning process, but only satisfies the commercial aspect of the detergent by helping to spread the detergent. This helps in the commercial success of a cleansing formulation. Since sebum has an inhibiting action on the bubble, more foam is produced in the second shampoo. In practice, it creates many small bubbles of air or other gases within a small volume of liquid, changing the surface tension of the liquid.

Surfactant - Cleansing agent. Cosmetic products used to cleanse the skin utilise the surface-active action that produces a lowering of the surface tension of the stratum corneum, facilitating the removal of dirt and impurities.

Surfactant - Emulsifying agent. Emulsions are thermodynamically unstable and are used to soothe or soften the skin and emulsify, so they need a specific, stabilising ingredient. This ingredient forms a film, lowers the surface tension and makes two immiscible liquids miscible. A very important factor affecting the stability of the emulsion is the amount of the emulsifying agent. Emulsifiers have the property of reducing the oil/water or water/oil interfacial tension, improving the stability of the emulsion and also directly influencing the stability, sensory properties and surface tension of sunscreens by modulating the filmometric performance.

Safety

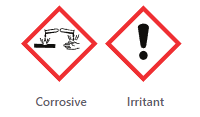

It is used in mild soaps and shampoos. However, it can cause eye irritation if used in large quantities. Since it is not mandatory to indicate the percentage or quantity of the chemical on labels, it is still difficult to know how much Sodium Laureth sulfate is in the product. The scientific literature that has dealt with this chemical compound for decades has concluded in favour of a recognition of the irritant properties of Sodium lauryl ether sulphate. Since it is not uncommon for ethylene oxide (1) and 1,4-Dioxane, a synthetic cyclic ether traditionally used as a stabiliser (2), to be found in this chemical compound during the production process, the IARC (International Agency for Research on Cancer ) warns that ethylene oxide is carcinogenic to humans (3) and 1,4-Dioxane is potentially carcinogenic to humans (4). The real problem is that no manufacturer declares SLES as free of these two compounds on the label. So we cannot know if and how much ethylene oxide and 1,4-dioxane are present in the product we have purchased. In addition, 1,4-dioxane does not degrade easily and is therefore considered to be a water pollutant that must be removed using special techniques (5).

The Cosmetic Ingredient Review (CIR) Expert Panel considers sodium laureth sulfate to be a skin and eye irritant, but not a sensitiser (6).

From the above, a rather negative picture emerges for SLES, and my opinion is to be cautious and not to buy products containing SLES unless the absence of ethylene oxide and 1,4-dioxane is clearly indicated.

It is also important not to mistake the acronyms SLES (Sodium lauryl polyoxyethylene ether sulfate Sodium Laureth Sulfate) with SLS (Sodium lauryl sulfate), also a surfactant but much less aggressive.

The most relevant studies on this chemical compound have been selected with a summary of their contents:

Typical characteristics of the commercial product Sodium lauryl polyoxyethylene ether sulfate Sodium Laureth Sulfate (SLES)

| Appearance | Liquid or clear transparent gel slightly yellow or white powder, fine. |

| Relative density | 1.05 |

| Maximum viscosity | 100 MPa.s |

| Active matter content, % | 70±2 |

| Unsulfated matter content, % | 3.0 max |

| Inorganic sulfate content, % | 2.0 max |

| pH value (1% aq.solution) | 7.0-9.5 |

| Dioxane, ppm | ≤70 |

| Sodium sulfate(%) | ≤1.5 |

| PSA | 84.04000 |

| LogP | 4.48150 |

| Safety |  |

|  |

|  |

- Molecular Formula: C14H29NaO5S

- Molecular Weight: 332.431 g/mol

- CAS: 15826-16-1

- EC Number: 239-925-1

- UNII 410Q7WN1BX

- DSSTox Substance ID: DTXSID2029298 DTXSID70274019

- MDL number

- PubChem Substance ID

- InChI=1S/C14H30O5S.Na/c1-2-3-4-5-6-7-8-9-10-11-12-18-13-14-19-20(15,16)17;/h2-14H2,1H3,(H,15,16,17);/q;+1/p-1

- InChl Key ASEFUFIKYOCPIJ-UHFFFAOYSA-M

- SMILES CCCCCCCCCCCCOCCOS(=O)(=O)[O-].[Na+]

- IUPAC sodium;2-dodecoxyethyl sulfate

- RTECS KK7890000

Synonyms:

- SLES

- Sodium dodecylpoly(oxyethylene) sulfate

- Sodium Alkyl Ether Sulfate

- Sodium laureth-5 sulfate

- Sodium laureth-8 sulfate

- Sodium dodeceth-1 sulfate

- Dodecyl sodium ethoxysulfate

- Sodium lauryl oxyethyl sulfate

- Sodium lauryl polyoxyethylene ether sulfate

- Sodium 2-(lauryloxy)ethyl sulfate

- Sodium 2-(dodecyloxy)ethyl sulfate

- Ethanol, 2-(dodecyloxy)-, hydrogen sulfate, sodium salt

- 2-(Dodecyloxy)ethyl sodium sulfate

- Etoxon EPA

- Sodium lauryl ethoxysulphate

- Sodium lauryl sulfate ethoxylate

- Sodium laureth-12 sulfate

- PEG-5 Lauryl ether sulfate, sodium salt

- PEG-7 Lauryl ether sulfate, sodium salt

- PEG-8 Lauryl ether sulfate, sodium salt

- PEG-12 Lauryl ether sulfate, sodium salt

- Sodium polyethylene glycol (7) lauryl ether sulfate

- Sodium polyethylene glycol 600 lauryl ether sulfate

- Polyoxyethylene (5) lauryl ether sulfate, sodium salt

- Polyoxyethylene (7) lauryl ether sulfate, sodium salt

- Polyoxyethylene (8) lauryl ether sulfate, sodium salt

- Polyoxyethylene (12) lauryl ether sulfate, sodium salt

- Polyethylene glycol (5) lauryl ether sulfate, sodium salt

- Polyethylene glycol 400 lauryl ether sulfate, sodium salt

- Polyethylene glycol 600 lauryl ether sulfate, sodium salt

- Dodecanol, ethoxylated, monoether with sulfuric acid, sodium salt

- Sodium laureth-3 sulfate

- Sodium laurylpoly(oxyethylene) sulfate

- Sodium polyoxyethylene (8) sulfate

- alpha-Sulfo-omega-(dodecyloxy)poly(oxy-1,2-ethanediyl) sodium salt

- Poly(oxy-1,2-ethanediyl), alpha-sulfo-omega-(dodecyloxy)-, sodium salt

- Glycols, polyethylene, mono(hydrogen sulfate), dodecyl ether, sodium salt

- Sodium polyoxyethylene (5) lauryl ether sulfate

- Sodium polyoxyethylene (7) lauryl ether sulfate

- Sodium polyoxyethylene (12) lauryl ether sulfate

- Sodium polyethylene glycol (5) lauryl ether sulfate

- 2-(Dodecyloxy)ethanol hydrogen sulfate sodium salt

- Laureth-8 carboxylic acid, sodium salt

- Polyethylene glycol sulfate monododecyl ether sodium salt

- Sodium polyethylene glycol 400 sulfate

- Polyethylene glycol (7) lauryl ether sulfate, sodium salt

- Sodium (lauryloxypolyethoxy)ethyl sulfate

- Sodium poly(oxyethylene) lauryl ether sulfate

- 15826-16-1

- Standapol ES 2

- Sodium 2-(dodecyloxy)ethyl sulphate

- Sodium laureth-7 sulfate

References______________________________________________________________________

(1) Vleugels LF, Pollet J, Tuinier R. Polycation-sodium lauryl ether sulfate-type surfactant complexes: influence of ethylene oxide length. J Phys Chem B. 2015 May 21;119(20):6338-47. doi: 10.1021/acs.jpcb.5b02043.

Abstract. Polyelectrolyte-surfactant complexes (PESC) are a class of materials which form spontaneously by self-assembly driven by electrostatic and hydrophobic interactions. PESC containing sodium lauryl ether sulfates (SLES) have found wide application in hair care products like shampoo. Typically, SLES with only one or two ethylene oxide (EO) groups are used for this application. We have studied the influence of the size of the EO block (ranging from 0 to 30 EO groups) on complexation with two model polycations: linear polyDADMAC and branched PEI. PESC size and electrostatic properties were determined during stepwise titration of buffered polycation solutions. The critical aggregation concentration (CAC) of PESC was determined by surface tension measurements and fluorescence spectroscopy. For polyDADMAC, there is no influence of the size of the EO block on the complexation behavior; the stiff polycation governs the structure formation. For PEI, it was seen that the EO block size does affect the structure of the complexes. The CAC value of the investigated complexes turns out to be rather independent of the EO block size; however, the CMC/CAC ratio decreases with increasing size of the EO block. This latter observation explains why the Lochhead-Goddard effect is most effective for small EO blocks.

(2) Black RE, Hurley FJ, Havery DC. Occurrence of 1,4-dioxane in cosmetic raw materials and finished cosmetic products. J AOAC Int. 2001 May-Jun;84(3):666-70.

Abstract. Surveys of cosmetic raw materials and finished products for the presence of the carcinogen 1,4-dioxane have been conducted by the U.S. Food and Drug Administration since 1979. Analytical methods are described for the determination of 1,4-dioxane in ethoxylated cosmetic raw materials and cosmetic finished products. 1,4-Dioxane was isolated by azeotropic atmospheric distillation and determined by gas chromatography using n-butanol as an internal standard. A solid-phase extraction procedure based on a previously published method for the determination of 1,4-dioxane in cosmetic finished products was also used. 1,4-Dioxane was found in ethoxylated raw materials at levels up to 1410 ppm, and at levels up to 279 ppm in cosmetic finished products. Levels of 1,4-dioxane in excess of 85 ppm in children's shampoos indicate that continued monitoring of raw materials and finished products is warranted.

(3) Ethylene oxide. IARC Monogr Eval Carcinog Risks Hum. 1994;60:73-159.

(4) 1,4-Dioxane. IARC Monogr Eval Carcinog Risks Hum. 1999;71 Pt 2(PT 2):589-602.

Wilbur S, Jones D, Risher JF, Crawford J, Tencza B, Llados F, Diamond GL, Citra M, Osier MR, Lockwood LO. Toxicological Profile for 1,4-Dioxane. Atlanta (GA): Agency for Toxic Substances and Disease Registry (US); 2012 Apr.

Abstract. This public health statement tells you about 1,4-dioxane and the effects of exposure to it. The Environmental Protection Agency (EPA) identifies the most serious hazardous waste sites in the nation. These sites are then placed on the National Priorities List (NPL) and are targeted for long-term federal clean-up activities. 1,4-Dioxane has been found in at least 31 of the 1,689 current or former NPL sites. Although the total number of NPL sites evaluated for this substance is not known, the possibility exists that the number of sites at which 1,4-dioxane is found may increase in the future as more sites are evaluated. This information is important because these sites may be sources of exposure, and exposure to this substance may be harmful. When a substance is released either from a large area, such as an industrial plant, or from a container, such as a drum or bottle, it enters the environment. Such a release does not always lead to exposure. You can be exposed to a substance only when you come in contact with it. You may be exposed by breathing, eating, or drinking the substance, or by skin contact. If you are exposed to 1,4-dioxane, many factors will determine whether you will be harmed. These factors include how much (the dose), how long (the duration), and how you come in contact with it. You must also consider any other chemicals you are exposed to and your age, sex, diet, family traits, lifestyle, and state of health.

(5) Scaratti G, De Noni Júnior A, José HJ, de Fatima Peralta Muniz Moreira R. 1,4-Dioxane removal from water and membrane fouling elimination using CuO-coated ceramic membrane coupled with ozone. Environ Sci Pollut Res Int. 2020 Jun;27(18):22144-22154. doi: 10.1007/s11356-019-07497-6.

Abstract. 1,4-Dioxane is a synthetic cyclic ether traditionally used as a chlorinated solvent stabilizer. It is a small molecule and recalcitrant compound that is difficult to remove by conventional processes and in this regard, there is a need for the development of new technologies. In this study, an innovative CuO-coated ceramic membrane (CM) reactor system that can be used to oxidize 1,4-dioxane dissolved in surface water by catalytic ozonation was developed. The effect of the thickness of the CuO deposited on the ceramic membrane surface on the permeability, fouling resistance, 1,4-dioxane removal, and toxicity was evaluated. The efficiency of the hybrid ozonation coupled to the use of a CuO-coated CM in 1,4-dioxane removal and the antifouling properties were assessed from TOC and 1,4-dioxane removal kinetics data. Reusability in four cycles was also tested. The performance of the CuO-coated CM remained stable during the four cycles of the reusability test. The ceramic membrane coated with CuO particles coupled with ozonation is appropriate for 1,4-dioxane degradation in the aqueous phase (45% efficiency, rate constant increased by a factor of 2.98 compared with the uncoated-hybrid process) and fouling removal (60 min to recovery the permeate flux).

(6) Robinson, Valerie C., et al. "Final report of the amended safety assessment of sodium laureth sulfate and related salts of sulfated ethoxylated alcohols." International journal of toxicology 29.4_suppl (2010): 151S-161S.

Abstract. Sodium laureth sulfate is a member of a group of salts of sulfated ethoxylated alcohols, the safety of which was evaluated by the Cosmetic Ingredient Review (CIR) Expert Panel for use in cosmetics. Sodium and ammonium laureth sulfate have not evoked adverse responses in any toxicological testing. Sodium laureth sulfate was demonstrated to be a dermal and ocular irritant but not a sensitizer. The Expert Panel recognized that there are data gaps regarding use and concentration of these ingredients. However, the overall information available on the types of products in which these ingredients are used and at what concentrations indicates a pattern of use. The potential to produce irritation exists with these salts of sulfated ethoxylated alcohols, but in practice they are not regularly seen to be irritating because of the formulations in which they are used. These ingredients should be used only when they can be formulated to be nonirritating.

| Evaluate |