| "Descrizione" by FRanier (9974 pt) | 2023-Nov-20 10:41 |

Review Consensus: 10 Rating: 10 Number of users: 1

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

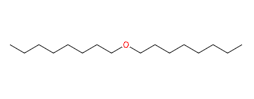

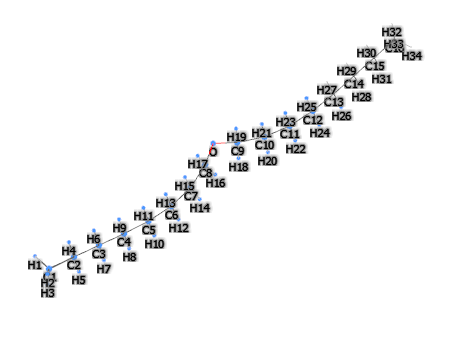

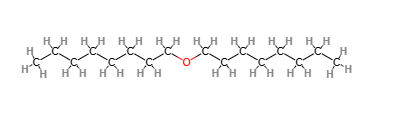

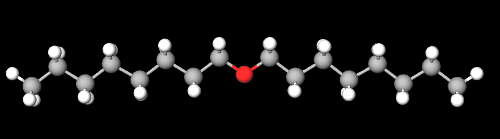

Dicaprylyl ether is a chemical compound extracted by a rather complex process involving a catalytic dehydration of octanol-1 in the presence of Cu at a temperature of 195-200°C for 8-12 hours. It can be obtained from palm oil and coconut oil.

The name describes the structure of the molecule:

- Dicaprylyl refers to the presence of two caprylic groups in the molecule. The caprylic group is derived from caprylic acid, a type of medium-chain fatty acid, and has the structure C8H17-.

- ether refers to a class of organic compounds that contain an ether group, an oxygen atom attached to two alkyl or aryl groups.

It appears as a colourless transparent liquid, stable, flammable and incompatible with strong oxidising agents.

Cosmetics

Skin conditioning agent. It is the mainstay of topical skin treatment as it has the function of restoring, increasing or improving skin tolerance to external factors, including melanocyte tolerance. The most important function of the conditioning agent is to prevent skin dehydration, but the subject is rather complex and involves emollients and humectants that can be added in the formulation.

Skin conditioning agent - Emollient. Emollients have the characteristic of enhancing the skin barrier through a source of exogenous lipids that adhere to the skin, improving barrier properties by filling gaps in intercorneocyte clusters to improve hydration while protecting against inflammation. In practice, they have the ability to create a barrier that prevents transepidermal water loss. Emollients are described as degreasing or refreshing additives that improve the lipid content of the upper layers of the skin by preventing degreasing and drying of the skin. The problem with emollients is that many have a strong lipophilic character and are identified as occlusive ingredients; they are oily and fatty materials that remain on the skin surface and reduce transepidermal water loss. In cosmetics, emollients and moisturisers are often considered synonymous with humectants and occlusives.

Solvent. It is the substance for dissolving or dispersing surfactants, oils, dyes, flavourings, bactericidal preservatives in solution.In fact, it dissolves other components present in a cosmetic formulation. Solvents are generally liquid (aqueous and non-aqueous).

It is also added as a generic excipient.

Medical

In the pharmaceutical industry it is used in dermatological formulations as an emollient (1).

Other uses

It has rheological properties to improve fluid flow (2).

For more details:

Typical commercial product characteristics Dicaprylyl ether

| Appearance | Colorless liquid |

| Boiling Point | 286-287°C |

| Melting Point | −7.6° |

| Flash Point | >110°C |

| Density | 0.806 g/mL at 25°C |

| Refraction Index | n20/D 1.433 |

| PSA | 9.23000 |

| LogP | 5.72400 |

| Loss on drying | ≤0.5% |

| SO4 | ≤0.1% |

| Cl | ≤0.01% |

|  |

|  |

- Molecular Formula C16H34O

- Molecular Weight 242.44

- Exact Mass

- CAS 629-82-3

- UNII 77JZM5516Z

- EC Number 211-112-6

- DSSTox Substance ID DTXSID20862324

- IUPAC 1-octoxyoctane

- InChl=1S/C16H34O/c1-3-5-7-9-11-13-15-17-16-14-12-10-8-6-4-2/h3-16H2,1-2H3

- InChl Key NKJOXAZJBOMXID-UHFFFAOYSA-N

- SMILES CCCCCCCCOCCCCCCCC

- MDL number MFCD00009563

- PubChem Substance ID 24855006

- ChEBI 88651

- RXCUI 1367138

- RTECS RH8800000

- NSC 28948

Synonyms :

- Caprylic ether

- 1,1’-oxybisoctane

- Dioctyl ether

- 1-octoxyoctane

References___________________________________________

(1) Marcato B, Guerra S, Vianello M, Scalia S. Migration of antioxidant additives from various polyolefinic plastics into oleaginous vehicles. Int J Pharm. 2003 May 12;257(1-2):217-25. doi: 10.1016/s0378-5173(03)00143-1.

Abstract. The migration of the antioxidant additives pentaerythrityl tetrakis(3,5-di-tert-butyl-4-hydroxyphenyl)propionate (Irganox 1010) and tris(2,4-di-tert-butylphenyl)phosphite (Irgafos 168) from polyolefinic packaging into oily vehicles was investigated. The polyolefins included in the study were from the following classes: isotactic polypropylene homopolymer (PP), ethylene-co-propylene random copolymer (RACO), ethylene-propylene heterophasic copolymer and ethylene-propylene amorphous copolymer blend (EP) and high-density polyethylene (HDPE). Each polymer was additioned with Irganox 1010 (0.15%, w/w) and Irgafos 168 (0.15%, w/w) and processed into blown bottles. To study the antioxidant release process, plastic sheets were cut from the bottles and dipped for various time intervals into a mixture of five oils (caprylic/capric triglyceride, cyclomethicone, dicaprylyl ether, isohexadecane and C(12-15) alkyl benzoate) representative of lipophilic excipients used in pharmaceutical and cosmetic formulations. After exposure to the oil medium, the non-migrated Irganox 1010 and Irgafos 168 were recovered from the polymeric matrices using microwave-assisted extraction with ethyl acetate-hexane and assayed by HPLC. The leaching of the two antioxidants varied remarkably depending on the polyolefin crystallinity and structure. The amount of Irganox 1010 transferred into the contact medium at 25 degrees C decreased in the order EP>RACO>PP>HDPE. The same polyolefin ranking was observed in the case of Irgafos 168, except for PP and HDPE which exhibited similar depletion of this additive. Migration of Irgafos 168 was greater than that of Irganox 1010 and the release of both antioxidants increased at higher temperature (50 degrees C). The obtained data are useful for the selection of polyolefinic matrices as raw-materials for the production of pharmaceutical and cosmetic containers.

(2) Kirilov P, Gauffre F, Franceschi-Messant S, Perez E, Rico-Lattes I. Rheological characterization of a new type of colloidal dispersion based on nanoparticles of gelled oil. J Phys Chem B. 2009 Aug 13;113(32):11101-8. doi: 10.1021/jp905260s.

Abstract. The rheological properties of a new type of colloidal dispersion based on nanoparticles of gelled oil have been characterized. The nanoparticles (mean diameter approximately 250 nm) were viscoelastic droplets of dicaprylyl ether gelled by 12-hydroxystearic acid (HSA) and were stabilized in aqueous solutions by cetyltrimethylammonium bromide. The effects of the volume fraction of the dispersed organogel phase and of the organogelator concentration upon viscoelasticity of the dispersion were investigated and compared to the corresponding emulsion (without HSA). The shear viscosity of the dispersions of organogel droplets and the elastic and viscous moduli (G' and G'') were found to increase when the proportion of organogelator was increased. More surprisingly, the shear-thinning behavior was also more pronounced. The rheological behavior of the dispersions could be explained by strong interactions between some gelled particles. This hypothesis was supported by electron microscopy observations showing some particles bridged together by ribbons of HSA fibers.

| Evaluate |