| "Descrizione" by FCS777 (5554 pt) | 2024-Oct-14 16:52 |

Review Consensus: 10 Rating: 10 Number of users: 1

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

Sodium Oleate is the sodium salt of oleic acid, a monounsaturated fatty acid commonly found in vegetable oils such as olive oil and sunflower oil. It is primarily used as an emulsifier, surfactant, and foaming agent in cosmetic and skincare products. Due to its ability to emulsify fats and oils, Sodium Oleate helps stabilize formulations and enhances cleansing by removing dirt and sebum from the skin and hair.

Chemical Composition and Structure

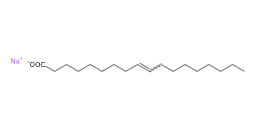

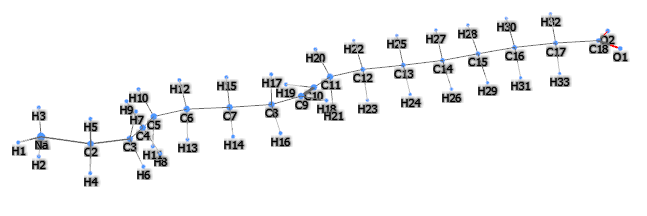

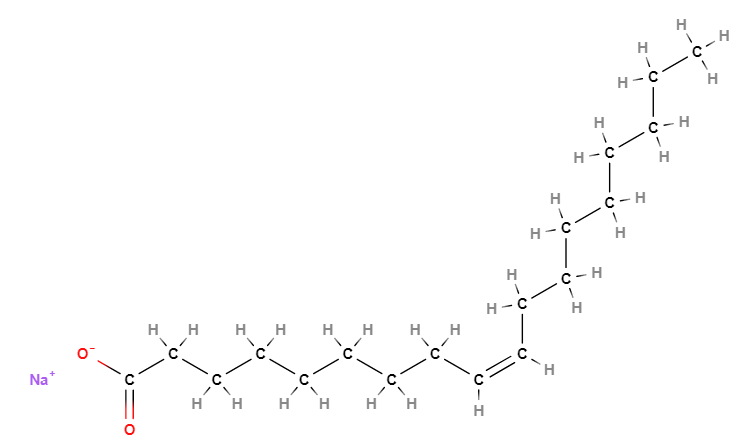

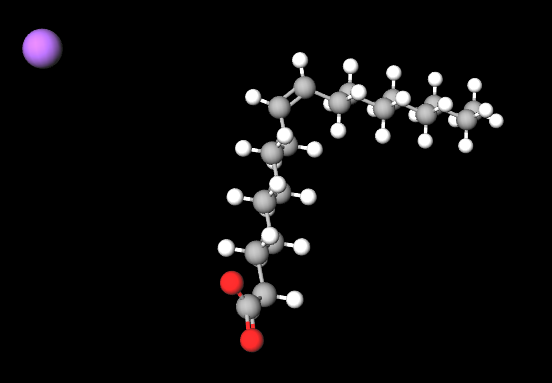

Sodium Oleate is a natural soap formed by the reaction of oleic acid with sodium hydroxide. Its chemical formula is C18H33NaO2, and it features a long hydrocarbon chain that makes it lipophilic, combined with a carboxylate group that provides water solubility. This structure makes it an excellent emulsifier for blending oily and aqueous substances, ideal in cleansing and moisturizing products.

The name describes the structure of the molecule:

- Sodium indicates the presence of sodium ions in the molecule.

- Oleate, derived from the word "oleic." It indicates that the molecule is a salt or ester of oleic acid, a monounsaturated fatty acid.

Description of the raw materials used in its production:

- Oleic Acid - Oleic acid is a monounsaturated fatty acid naturally found in various vegetable oils, such as olive oil and sunflower oil. It is extracted from these sources or chemically synthesized. Oleic acid is the main component of sodium oleate.

- Sodium - Sodium is a chemical element found in many compounds. In the production of sodium oleate, oleic acid reacts with sodium hydroxide (NaOH) to form sodium oleate. This chemical reaction involves the replacement of the hydroxyl group of oleic acid with a sodium atom.

Production Process

Sodium Oleate is produced through a saponification reaction, where oleic acid, derived from vegetable oils, reacts with sodium hydroxide (NaOH). This process creates the sodium salt of oleic acid, which is purified for use in cosmetic and skincare products.

- Saponification - Oleic acid is reacted with sodium hydroxide in a saponification reaction. During this reaction, the carboxylic acid group of oleic acid reacts with sodium hydroxide, forming sodium oleate and water. This reaction results in the formation of a sodium salt of oleic acid.

- Purification - The crude product obtained from the saponification reaction is purified to remove any impurities or by-products. This can be done through processes such as filtration, crystallization, or centrifugation.

- Drying - The purified sodium oleate is dried to remove residual moisture and obtain a powder or dry solid.

- Quality Control - The dried sodium oleate undergoes quality control checks to ensure its purity, stability, and compliance with industry standards.

Physical Properties

Sodium Oleate appears as a white powder or solid, soluble in both water and oils. At room temperature, it can form a stable foam, which makes it useful in soaps and detergents. It also has emollient properties, leaving the skin soft after cleansing. Its ability to stabilize emulsions makes it a key ingredient in creams and lotions.

It occurs as a white or yellowish powder that is soluble in water and ethyl alcohol; insoluble in benzene.

What it is used for and where

Medical

Sodium oleate can induce disturbances of lipid metabolism and lipid deposition in HepG2 cells (1). It is also considered to be an effective new therapy to improve antibiotic deficiency treatment towards biofilm resistance (2) and an improver of chrysin oral absorption (3).

Pure sodium oleate is used for the activation of protein kinase C in liver cells.

Cosmetics

Viscosity-stable anionic surfactant in the production of soaps, creams and personal care products as it improves the performance of polymer systems with regard to viscosity and other rheological properties.

Cleansing agent. Ingredient that cleanses skin without exploiting the surface-active properties that produce a lowering of the surface tension of the stratum corneum.

Surfactant - Emulsifying agent. Emulsions are thermodynamically unstable and are used to soothe or soften the skin and emulsify, so they need a specific, stabilising ingredient. This ingredient forms a film, lowers the surface tension and makes two immiscible liquids miscible. A very important factor affecting the stability of the emulsion is the amount of the emulsifying agent. Emulsifiers have the property of reducing the oil/water or water/oil interfacial tension, improving the stability of the emulsion and also directly influencing the stability, sensory properties and surface tension of sunscreens by modulating the filmometric performance.

Surfactant - Cleansing agent. Cosmetic products used to cleanse the skin utilise the surface-active action that produces a lowering of the surface tension of the stratum corneum, facilitating the removal of dirt and impurities.

Viscosity control agent. It controls and adapts, Increasing or decreasing, viscosity to the required level for optimal chemical and physical stability of the product and dosage in gels, suspensions, emulsions, solutions.

Other uses

- Plastics. Used in the processing of various soft PVC products, such as films, foils, cable materials and moulded products, artificial leather, Cold resistant plasticiser.

- Waterproofing agent in textiles.

- Food packaging with the exception of fatty foods.

- Nitrocellulose varnish, which makes the varnish film with increased elasticity tensile strength.

- Synthetic rubbers with good softening effect.

- Organic solvent and stationary liquid for gas chromatography (methanol and methylene chloride as solvent with a maximum use temperature of 150°C) separates various oxygenated, aromatic and unsaturated compounds.

- Mineral processing

Health and Safety Considerations

Safety in Use

Sodium Oleate is considered safe for use in cosmetics and personal care products. It is well tolerated by the skin and is not known to cause significant irritation when used in appropriate concentrations. Major regulatory authorities, such as the European Union and the FDA, permit its use in cosmetics.

Allergic Reactions

Allergic reactions to Sodium Oleate are rare. However, individuals with sensitive or reactive skin are advised to perform a patch test before use.

Toxicity and Carcinogenicity

It has been widely used and tested in personal care products and is considered safe for long-term use.

Environmental Considerations

Sodium Oleate is biodegradable and considered environmentally friendly. It is derived from renewable resources, such as vegetable oils, and poses no significant risk to the ecosystem when used properly.

Regulatory Status

Sodium Oleate is approved for use in cosmetic products by major regulatory authorities, including the European Union and the FDA in the United States. It is widely used in cleansers and formulations for skin and hair care.

Typical commercial product characteristics Sodium oleate

| Appearance | White powder to slightly yellow |

| Assay | ≥99.0% |

| Boiling Point | 359.999ºC at 760 mmHg |

| Melting Point | 232-235°C(lit.) |

| Flash Point | 270.099ºC |

| Density | 0.9 g/cm3 |

| Loss on drying | ≤5.0% |

| Free alkali | ≤0.5% |

| Fatty acid value | 195~204 |

| Iodine | 80~100 Gl/100g |

| Shelf life | 2 years |

| Storage | 2-8°C |

| PSA | 40.13000 |

| LogP | 4.77380 |

| pKa | 4.46(at 25℃) |

| Safety |  |

|  |

|  |

- Molecular Formula C18H33NaO2

- Linear Formula CH3(CH2)7CH=CH(CH2)7COONa

- Molecular Weight 304.4

- Exact Mass 304.237823

- CAS 143-19-1

- UNII 399SL044HN

- EC Number 205-591-0

- DSSTox Substance ID DTXSID7021077

- IUPAC sodium;(Z)-octadec-9-enoate

- InChI=1S/C18H34O2.Na/c1-2-3-4-5-6-7-8-9-10-11-12-13-14-15-16-17-18(19)20;/h9-10H,2-8,11-17H2,1H3,(H,19,20);/q;+1/p-1/b10-9-;

- InChl Key BCKXLBQYZLBQEK-KVVVOXFISA-M

- SMILES CCCCCCCCC=CCCCCCCCC(=O)[O-].[Na+]

- MDL number MFCD00004438

- PubChem Substance ID 24898044

- ChEBI 81860

- RXCUI 32559

- Beilstein 4046357

- RTECS RK1200000

- HS Code 2916150000

Synonyms

- Oleic acid, sodium salt

- sodium;(Z)-octadec-9-enoate

- Eunatrol

- Sodium 9-octadecenoate

- Olate flakes

- Sodiumoleate

- Sodiumoleate

- sodium (Z)-octadec-9-enoate

References___________________________________________________________________

(1) Norikura T, Mukai Y, Fujita S, Mikame K, Funaoka M, Sato S. Lignophenols decrease oleate-induced apolipoprotein-B secretion in HepG2 cells. Basic Clin Pharmacol Toxicol. 2010 Oct;107(4):813-7. doi: 10.1111/j.1742-7843.2010.00575.x.

(2) Mohamed AMHA, Vladimirovna SN, Grigorievich ZV, Borisovna PA, Ivanovich SV. Sodium Oleate Increases Ampicillin Sensitivity in Methylophilus quaylei Biofilms on Teflon and Polypropylene. Curr Pharm Biotechnol. 2019;20(3):261-270. doi: 10.2174/1389201020666190222191656.

(3) Dong D, Quan E, Yuan X, Xie Q, Li Z, Wu B. Sodium Oleate-Based Nanoemulsion Enhances Oral Absorption of Chrysin through Inhibition of UGT-Mediated Metabolism. Mol Pharm. 2017 Sep 5;14(9):2864-2874. doi: 10.1021/acs.molpharmaceut.6b00851.

Abstract. Oral bioavailability of flavonoids (and many phenolic drugs) is severely limited by extensive first-pass glucuronidation. Here we aimed to determine the modulatory effects of commonly used pharmaceutical excipients (PEs) on UDP-glucuronosyltransferase (UGT) activities and to evaluate the potential of nanoemulsions containing a UGT-inhibitory PE for oral absorption enhancement of chrysin, a model flavonoid. The effects of PEs on glucuronidation were determined using tissue (liver and intestine) microsomes, expressed UGT1A1 enzyme, and UGT1A1-overexpressing HeLa cells. Nanoemulsions were prepared using a modified emulsification technique and subsequently characterized by particle size, zeta-potential, morphology, and in vitro drug release. Pharmacokinetic studies were performed with rats to assess the effects of nanoemulsions on the metabolism and pharmacokinetics of chrysin. Of 21 PEs, five (i.e., Brij 35, Brij 58, labrasol, sodium oleate, and Tween 20) significantly inhibited chrysin glucuronidation. Of note, sodium oleate was the most potent inhibitor of glucuronidation. Eight PEs including Tween 80 had no effects on glucuronidation of chrysin. The chrysin nanoemulsions prepared with sodium oleate (named SO-NE) were spherical or near-spherical (particle size, 83.2 nm; zeta-potential, -43.7 mV; entrapment efficiency, 89.5%). The reference nanoemulsions prepared with Tween 80 (T80-NE) were highly similar to SO-NE in terms of particle size, zeta-potential, and drug release. It was demonstrated in pharmacokinetic studies that SO-NE led to a 4.3-fold increase in systemic exposure of chrysin and a 3.5-fold increase in Cmax value, whereas T80-NE did not cause any changes in chrysin pharmacokinetics. In conclusion, sodium oleate-based nanoemulsions greatly enhanced oral absorption of chrysin. Oral absorption enhancement of chrysin was attained through targeted inhibition of first-pass glucuronidation by sodium oleate.

| Evaluate |