| "Descrizione" by AColumn (9336 pt) | 2024-Feb-01 15:09 |

Review Consensus: 10 Rating: 10 Number of users: 1

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

Maltodextrins (maltodextrin) are one or more polymers useful for the absorption of sugars and to provide energy. It is obtained by enzymatic or acid hydrolysis from maize or potato starch and generally shows high solubility in water, low viscosity.

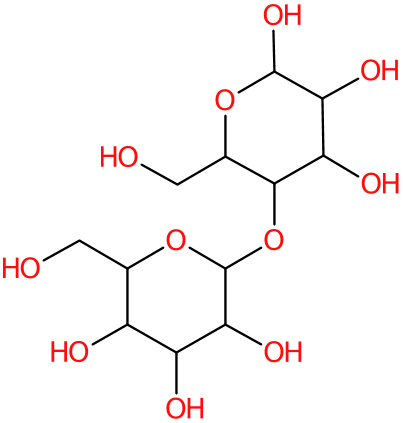

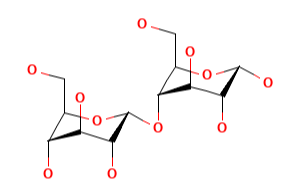

In practice they are a group of complex carbohydrates, or polysaccharides, which are widely used in the food and beverage industry for their unique functional properties. The term "maltodextrin" applies to any starch hydrolysis product containing less than 20 glucose units and, as such, is a broad term covering a wide range of products.

The very name "maltodextrin" provides some information about the nature of these molecules:

- "Malt-" is derived from maltose, a disaccharide composed of two glucose molecules. Maltose is one of the products that can be formed when starch is broken down.

- "-dextrin" refers to dextrins, a group of low molecular weight carbohydrates produced by starch hydrolysis.

The process of maltodextrin synthesis involves several steps:

- Starch gelatinization: Raw starch is mixed with water to form a suspension. This dough is heated to break down the intermolecular bonds of starch molecules, which cause the release of starch granules (gelatinization).

- Hydrolysis: Gelatinized starch is hydrolysed under the action of enzymes (amylase) or acids. This process breaks down long starch molecules into shorter dextrin chains. The degree of hydrolysis affects the properties of maltodextrin, such as sweetness and solubility. A higher degree of hydrolysis results in a sweeter and more soluble product.

- Desolventization: the resulting dextrin solution is then filtered to remove any insoluble substances. The filtrate, which contains maltodextrin, is then de-dusted by evaporation to remove excess water.

- Drying: The concentrated maltodextrin solution is then spray dried to obtain the final product as a white powder.

- Packaging: The maltodextrin powder is then packaged for distribution and use.

It takes the form of a white flaky powder.

What it is used for and where

It is used as an additive in the food industry to sweeten foods.

More digestible than other carbohydrates, it is a white powder that provides only 4 calories per gram and fewer fibers, fats and proteins.

There are several types of maltodextrin and the most common are (1): DE-2, DE-6, DE-12, DE-17, DE-19 with the following uses

- in preserving the antioxidant content of fruit (2)

- in bringing ice creams to the right viscosity, melting speed and acidity (3)

- stabilising iron-enriched milk formula (4)

- the high content of hard-to-digest starch, dietary fibre and its complete solubility make maltodextrin a promising ingredient for increasing dietary fibre content in a wide range of foods, particularly in beverages, dairy products, creams and soups (5)

- the inclusion of tapioca maltodextrin in natural, low-fat cheese can improve texture and acceptability compared to low-fat cheeses without maltodextrin . The recommended level of tapioca maltodextrin is 1.1% by weight of the mixture (6)

- microencapsulation with maltodextrin is a technique in which sensitive compounds are encapsulated by a material or coating that protects them from factors that can cause damage, such as light and oxygen (7)

Medical

- treatment with maltodextrin and ascorbic acid stimulates repair of chronic wound tissue by changing the phase of inflammation and modifying collagen turnover directly through the fibroblast response (8)

- counteracts the action of Acinetobacter baumannii and Staphylococcus aureus, important nosocomial pathogens commonly found in biofilm-infected wounds (9)

Cosmetics

- Absorbent. Absorbs substances dispersed or dissolved in aqueous solutions, water/oil, oil/water.

- Binder agent. Ingredient that is used in cosmetic, food and pharmaceutical products as an anti-caking agent with the function of making the product in which it is incorporated silky, compact and homogenous. The binder, either natural such as mucilage, gums and starches or chemical, may be in the form of a powder or liquid.

- Emulsion stabiliser. Emulsions are thermodynamically unstable. Emulsion stabilisers improve the formation and stability of single and double emulsions. as well as their shelf-life. It should be noted that in the structure-function relationship, the molar mass of the ingredient used plays an important role.

- Film-forming agent. It produces, upon application, a very thin continuous film with an optimal balance of cohesion, adhesion and stickiness on skin, hair or nails to counteract or limit damage from external phenomena such as chemicals, UV rays and pollution.

- Hair conditioning agent. A significant number of ingredients with specific and targeted purposes may co-exist in hair shampoo formulations: cleansers, conditioners, thickeners, matting agents, sequestering agents, fragrances, preservatives, special additives. However, the indispensable ingredients are the cleansers and conditioners as they are necessary and sufficient for hair cleansing and manageability. The others act as commercial and non-essential auxiliaries such as: appearance, fragrance, colouring, etc. Hair conditioning agents have the task of increasing shine, manageability and volume, and reducing static electricity, especially after treatments such as colouring, ironing, waving, drying and brushing. They are, in practice, dispersants that may contain cationic surfactants, thickeners, emollients, polymers. The typology of hair conditioning agents includes: intensive conditioners, instant conditioners, thickening conditioners, drying conditioners. They can perform their task generally accompanied by other different ingredients.

- Skin conditioning agent. It is the mainstay of topical skin treatment as it has the function of restoring, increasing or improving skin tolerance to external factors, including melanocyte tolerance. The most important function of the conditioning agent is to prevent skin dehydration, but the subject is rather complex and involves emollients and humectants that can be added in the formulation.

Su questo ingrediente sono stati selezionati gli studi più rilevanti con una sintesi dei contenuti:

|  |

- Molecular Formula C12H22O11

- Molecular Weight 342.30

- Exact Mass 180.063385

- CAS 9050-36-6

- UNII

- EC Number

- DSSTox Substance ID

- IUPAC (3S,6R)-2-(hydroxymethyl)-6-[(3S,6S)-4,5,6-trihydroxy-2-(hydroxymethyl)oxan-3-yl]oxyoxane-3,4,5-triol

- InChI=1S/C12H22O11/c13-1-3-5(15)6(16)9(19)12(22-3)23-10-4(2-14)21-11(20)8(18)7(10)17/h3-20H,1-2H2/t3?,4?,5-,6?,7?,8?,9?,10-,11+,12-/m1/s1

- InChl Key GUBGYTABKSRVRQ-JTGJSBPZSA-N

- SMILES C(C1C(C(C(C(O1)OC2C(OC(C(C2O)O)O)CO)O)O)O)O

- MDL number MFCD00146679

- PubChem Substance ID

- SCHEMBL 12278702

- NACRES NA.23

(1) Castro N, Durrieu V, Raynaud C, Rouilly A. Influence of DE-value on the physicochemical properties of maltodextrin for melt extrusion processes. Carbohydr Polym. 2016 Jun 25;144:464-73. doi: 10.1016/j.carbpol.2016.03.004.

(2) Araujo-Díaz SB, Leyva-Porras C, Aguirre-Bañuelos P, Álvarez-Salas C, Saavedra-Leos Z. Evaluation of the physical properties and conservation of the antioxidants content, employing inulin and maltodextrin in the spray drying of blueberry juice. - Carbohydr Polym. 2017 Jul 1;167:317-325. doi: 10.1016/j.carbpol.2017.03.065.

(3) Azari-Anpar M, Khomeiri M, Ghafouri-Oskuei H, Aghajani N. - Response surface optimization of low-fat ice cream production by using resistant starch and maltodextrin as a fat replacing agent. J Food Sci Technol. 2017 Apr;54(5):1175-1183. doi: 10.1007/s13197-017-2492-0.

(4) Pizarro F, Olivares M, Maciero E, Krasnoff G, Cócaro N, Gaitan D Iron Absorption from Two Milk Formulas Fortified with Iron Sulfate Stabilized with Maltodextrin and Citric Acid. Nutrients. 2015 Oct 30;7(11):8952-9. doi: 10.3390/nu7115448.

(5) Toraya-Avilés R, Segura-Campos M, Chel-Guerrero L, Betancur-Ancona D. Some Nutritional Characteristics of Enzymatically Resistant Maltodextrin from Cassava (Manihot esculenta Crantz) Starch. - Plant Foods Hum Nutr. 2017 Jun;72(2):149-155. doi: 10.1007/s11130-017-0599-0.

(6) Iakovchenko NV, Arseneva TP. - Tapioca maltodextrin in the production of soft unripened cheese. Acta Sci Pol Technol Aliment. 2016 Jan-Mar;15(1):47-56. doi: 10.17306/J.AFS.2016.1.5.

(7) Paula da Silva Dos Passos A, Madrona GS, Marcolino VA, Baesso ML, Matioli G. The Use of Thermal Analysis and Photoacoustic Spectroscopy in the Evaluation of Maltodextrin Microencapsulation of Anthocyanins from Juçara Palm Fruit (Euterpe edulis Mart.) and Their Application in Food. Food Technol Biotechnol. 2015 Dec;53(4):385-396.

(8) Salgado RM, Cruz-Castañeda O, Elizondo-Vázquez F, Pat L, De la Garza A, Cano-Colín S, Baena-Ocampo L, Krötzsch E. Maltodextrin/ascorbic acid stimulates wound closure by increasing collagen turnover and TGF-β1 expression in vitro and changing the stage of inflammation from chronic to acute in vivo. - J Tissue Viability. 2017 May;26(2):131-137. doi: 10.1016/j.jtv.2017.01.004.

(9) Sultana ST, Call DR, Beyenal H. Maltodextrin enhances biofilm elimination by electrochemical scaffold. Sci Rep. 2016 Oct 26;6:36003. doi: 10.1038/srep36003.

| Evaluate |