Guar hydroxypropyltrimonium chloride (cationic guar gum) is a chemical compound, cationic polymer derived from Guar gum. The chemical synthesis process takes place through a chemical reaction of etherification with quaternary ammonium compounds.

The name describes the structure of the molecule:

- Guar is derived from the guar plant, particularly the endosperm of guar seeds. The seeds are decorticated, ground and checked to obtain guar gum, which is a polysaccharide composed of galactose of sugars and mannose.

- Hydroxypropyltrimonium is a quaternary ammonium group. Quaternary ammonium compounds are organic nitrogen compounds used as disinfectants, surfactants, softeners and as antistatic agents in shampoos and hair conditioners. In this case, the hydroxypropyltrimonium group is chemically attached to guar gum to give it a positive charge, which can help it bind to negatively charged surfaces of hair and skin.

- Chloride is a simple ion, Cl- which is often found in salts and is used here as a counterion to balance the positive charge of the hydroxypropyltrimonium group.

The synthesis process takes place in different steps:

- Preparation of guar gum. The seeds are peeled, ground and sieved to obtain guar gum.

- Activation of guar gum by increasing the pH using a base such as sodium hydroxide (NaOH).

- Propilation. Activated guar gum is then reacted with propylene oxide. This step introduces hydroxypropyl groups to guar gum.

- Quaternization. Hydroxypropyl guar is then reacted with a quaternary ammonium compound, typically a tertiary amine such as trimethylamine, in the presence of an alkylating agent such as an alkyl halide. This phase introduces trimonium chloride groups, resulting in the formation of Guar hydroxypropyltrimonium chloride.

Industrially it occurs as a fine, yellow powder, highly soluble in hot and cold water.

What it is used for and where it is used

Antistatic conditioner in cosmetic products and compatible with anionic, cationic, non-ionic and amphoteric surfactants Hair conditioner and gel, body cleanser, facial cleanser. In the hair it is able to form a film, acts as a protection reducing possible irritation caused by other surfactants, moisturising and improving combing as it has a lubricating effect.

Film-forming agent. It produces, upon application, a very thin continuous film with an optimal balance of cohesion, adhesion and stickiness on skin, hair or nails to counteract or limit damage from external phenomena such as chemicals, UV rays and pollution.

Skin conditioning agent. It is the mainstay of topical skin treatment as it has the function of restoring, increasing or improving skin tolerance to external factors, including melanocyte tolerance. The most important function of the conditioning agent is to prevent skin dehydration, but the subject is rather complex and involves emollients and humectants that can be added in the formulation.

Viscosity control agent. It controls and adapts, Increasing or decreasing, viscosity to the required level for optimal chemical and physical stability of the product and dosage in gels, suspensions, emulsions, solutions.

It is a modest anti-inflammatory and may have a softening effect on the skin, but no scientific study has so far confirmed this property.

The normal level of use is 0.2-1% by weight.

Commercial applications

Hair Conditioning Agent. Guar Hydroxypropyltrimonium Chloride is used in conditioners and hair treatments to detangle and condition the hair, making it soft and manageable.

Antistatic Agent. Used in hair products to reduce static electricity, making the hair more manageable.

Thickening Agent in Cosmetic Products. Used to increase the viscosity of shampoos, conditioners, and other cosmetic products.

Emulsifying and Stabilizing Agent. Helps to stabilize emulsions in cosmetic products, preventing the separation of components.

Film-Forming Agent. Forms a thin film on the surface of the hair, enhancing shine and protecting it from environmental damage.

Guar hydroxypropyltrimonium chloride studi

Typical optimal commercial product characteristics Guar hydroxypropyltrimonium chloride

| Appearance | Fine, yellow powder. |

| Dispersibility in water | Good |

| Boiling Point | >300 °C(lit.) |

| Density | 1.3 g/mL at 25 °C(lit.) |

| pH (1% aqueous solution) | 8.0-11.0 |

| Purity,% ≥ | 98-99 |

| Loss on drying,%≤ | 13 |

| Ash content (%) | ≤3 |

| Viscosity (20℃, cps) | ≥3000 |

| Nitrogen content (%) | 1.3-1.7 |

| Boron | Yes |

| Total bacteria | ≤500 cfu/g |

| Saccharomycetes | ≤100 cfu/g |

| Shelf life | 2 years |

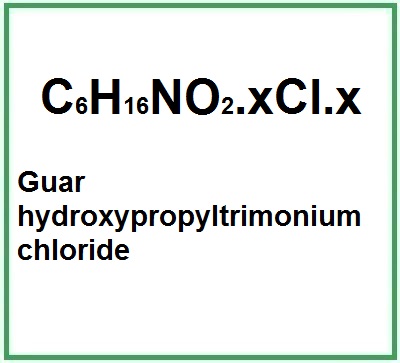

- Molecular Formula : C6H16NO2.xCl.x

- Average molecular weight approx. 2.000.000 g/mol

- CAS : 65497-29-2

- EC Number 613-809-4

- UNII B16G315W7A

- DSSTox Substance ID DTXSID6095459

Sinonimi :

- Cationic Guar Gum

- Guar,2-hydroxy-3-trimethylammoniopropylether,chloride

- {3-[(6-{[6-({[4,5-dihydroxy-2-(hydroxymethyl)oxan-3-yl]methoxy}methyl)-4,5-dihydroxyoxan-2-yl]methoxy}-3,4,5-trihydroxyoxan-2-yl)methoxy]-2-hydroxypropyl}trimethylazanium chloride

References____________________________________________________________________

Screening Assessment Report Template GEGAC

Erazo-Majewicz P, Roberts-Howard C, Oldham E, Lynch C, Graham J, Usher CR, Joneja S. Linking enhanced deposition agent functionality with aesthetic performance. J Cosmet Sci. 2011 Mar-Apr;62(2):101-8.

Abstract

This study examines the cationic polymers 1) guar hydroxypropyltrimonium chloride polymers (GHPTC), 2) acrylamidopropyltrimonium chloride/acrylamide copolymer (APTAC/Acm), 3) polyquaternium polymers (PQ-10, PQ-7, PQ-67), and 4) a new polymer system approach for their a) deposition efficiency (as measured by quantifying oils deposited on virgin hair) and b) ability to deliver good wet and dry lubricity to the hair from a cleansing formulation as measured by comb energy and friction characteristics of the hair samples. Conditioning polymer technology approaches 1) acrylamidopropyltrimonium chloride/acrylamide copolymer, 2) a guar hydroxypropyltrimonium chloride polymer, and 3) the new polymer system approach deliver superior deposition of natural conditioning oils and dimethicone materials from anionic/amphoteric surfactant cleansing formulations. These new polymer technologies offer formulators the ability to improve uniformity of deposition as well as deposition efficiency of conditioning agents onto hair, and target the desired hair lubricity.

Wang M, Preston N, Xu N, Wei Y, Liu Y, Qiao J. Promoter Effects of Functional Groups of Hydroxide-Conductive Membranes on Advanced CO2 Electroreduction to Formate. ACS Appl Mater Interfaces. 2019 Feb 20;11(7):6881-6889. doi: 10.1021/acsami.8b11845.

Abstract

The electrochemical reduction of CO2 at ambient conditions provides a latent solution of turning waste greenhouse gases into commodity chemicals or fuels; however, a satisfactory ion-conducting membrane for maximizing the performance of a CO2 electrolyzer has not been developed. Here, we report the synthesis of a sequence of hydroxide-conductive polymer membranes, which are based on polymer composites of poly(vinyl alcohol)/Guar hydroxypropyltrimonium chloride, for use in CO2 electrolysis. The effect of different membrane functional groups, including thiophene, hydroxybenzyl, and dimethyloctanal, on the efficiency and selectivity of CO2 electroreduction to formate is thoroughly evaluated. The membrane incorporating thiophene groups exhibits the highest Faradaic efficiency of 71.5% at an applied potential of -1.64 V versus saturated calomel electrode (SCE) for formate. In comparison, membranes containing hydroxybenzyl and dimethyloctanal groups produced lower efficiencies of 67.6 and 68.6%, respectively, whereas the commercial Nafion 212 membrane was only 57.6% efficient. The improved efficiency and selectivity of membranes containing thiophene groups are attributed to a significantly increased hydroxide conductivity (0.105 S cm-1), excellent physicochemical properties, and the simultaneous attenuation of formate product crossover.

![]() Guar hydroxypropyltrimonium chloride

Guar hydroxypropyltrimonium chloride