- Field and laboratory measurement of vibration in terms of acceleration, velocity and displacement together with piezoelectric accelerometer and voltmeter or measuring amplifier

- Field recording of vibration and other signals together with portable tape recorders and level recorders

- Underwater sound measurements with hydrophone

- Mechanical impedance measurements

- Charge Input

- 3 digit conditioning to transducer sensitivity

- Unified output ratings for simplified system calibration

- High sensitivity up to 10 V/pC

- Built-in integrators for displacement and velocity

- Switchable low and high frequency limits

- Built-in test oscillator

CHARGE INPUT:

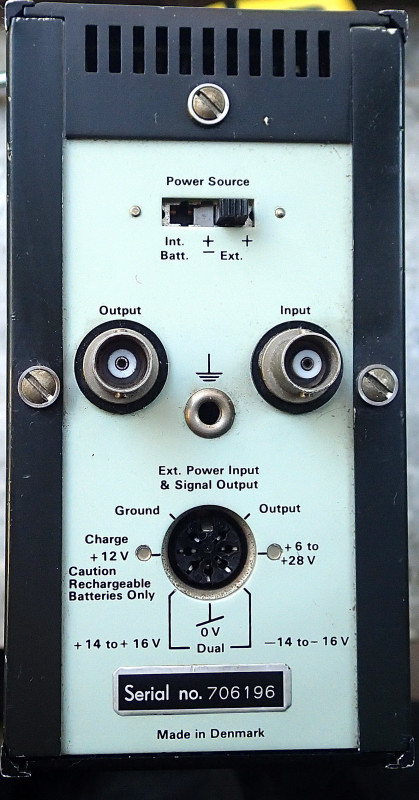

Via 10-32 NF and BNC coaxial socket

Max. Input: ~105 pC

SENSITIVITY CONDITIONING:

3 digit dial-in of transducer sensitivity from 0.1 to 10.99 pC/ms-2

AMPLIFIER SENSITIVITY:

0.01 mV to 10 V/pC corresponding to −40 to +80 dB with transducer capacitance of 1 nF

CALIBRATED OUTPUT RATINGS:

Selectable in 10 dB steps

Acceleration: 0.1 mV to 1 V/ms-2

Velocity: 10 mV to 100 V/ms-1

Displacement: 0.1 mV to 10 V/mm

SIGNAL OUTPUT:

Via 10-32 NF and BNC coaxial socket

Max. Output: 8 V (8 mA) peak

Output Impedance: DC Offset: <±50 mV

FREQUENCY RANGE:

Acceleration : Switchable 0.2 or 2 Hz to 100 kHz

Velocity: Switchable 1 or 10 Hz to 10 kHz

Displacement: Switchable1or10 Hz to 1 kHz –10% limits quoted — see Fig. 3

LOW–PASS FILTER:

Switchable −10% limits of 100 Hz, 1 kHz, 3 kHz, 10 kHz, 30 kHz and >100 kHz with attenuation slope of 40 dB/decade

INHERENT NOISE (2 Hz to 22 kHz):

5 × 10-3 pC referred to input with maximum sensitivity and 1 nF transducer capacitance

TEST OSCILLATOR:

159 Hz (ω = 1000 rad/s) sinusoid, factory preset for test level of 1 V

OVERLOAD INDICATOR:

Overload LED lights when input or output of amplifier is overloaded by signals of too high a peak level

RISE TIME: ~2.5 V/µs

Power Supply

Int. Battery: Three 1.5 V alkaline cells, IEC Type LR 20, provide approximately 100 hours use

Ext. Source: +6 to +28 V (55 mA) single or ±14 V (14 mA) dual polarity DC

Dimensions and Weight

Height: 132.6 mm (5.2″)

Width: 69.5 mm (2.7″)

Depth: 200 mm (7.9″)

Weight: 1.45 kg (3.2 lb) including batteries

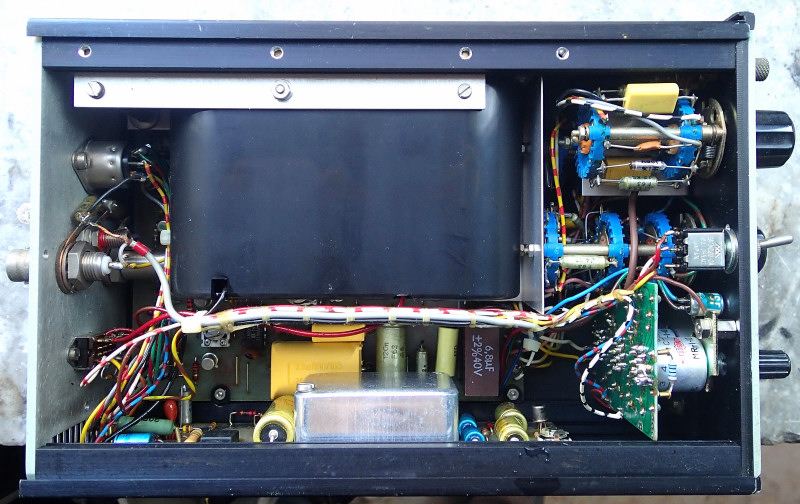

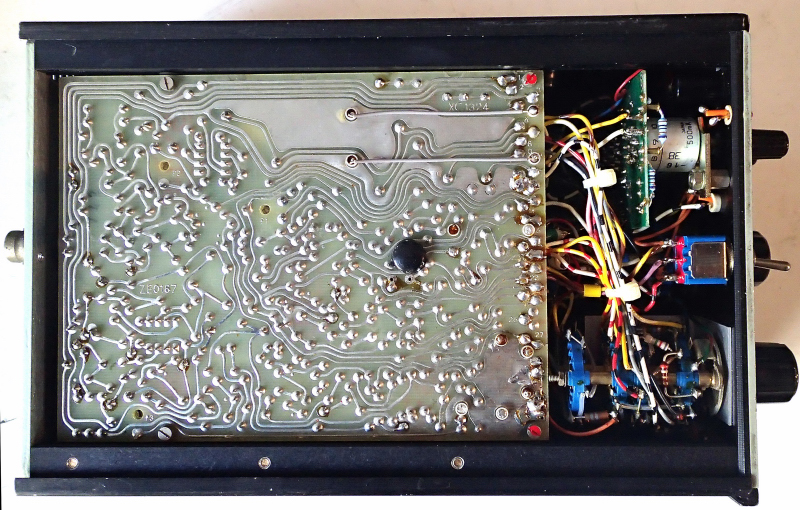

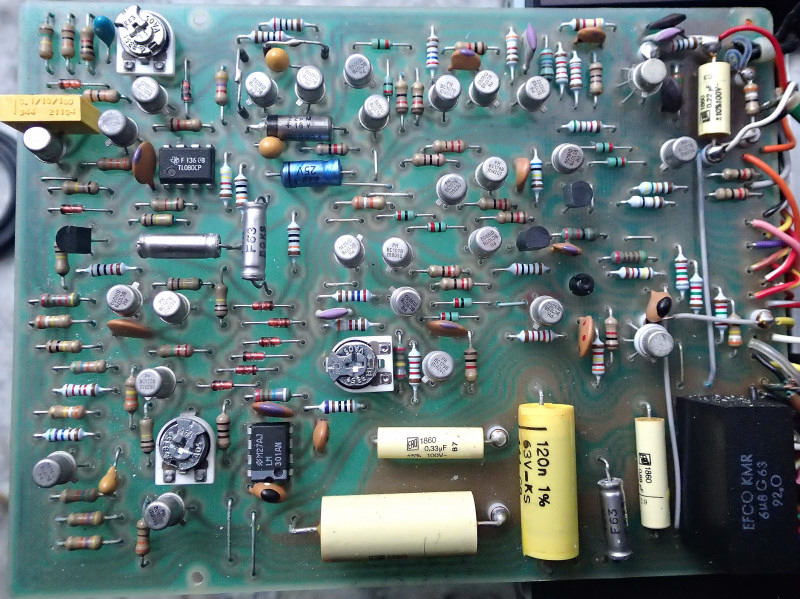

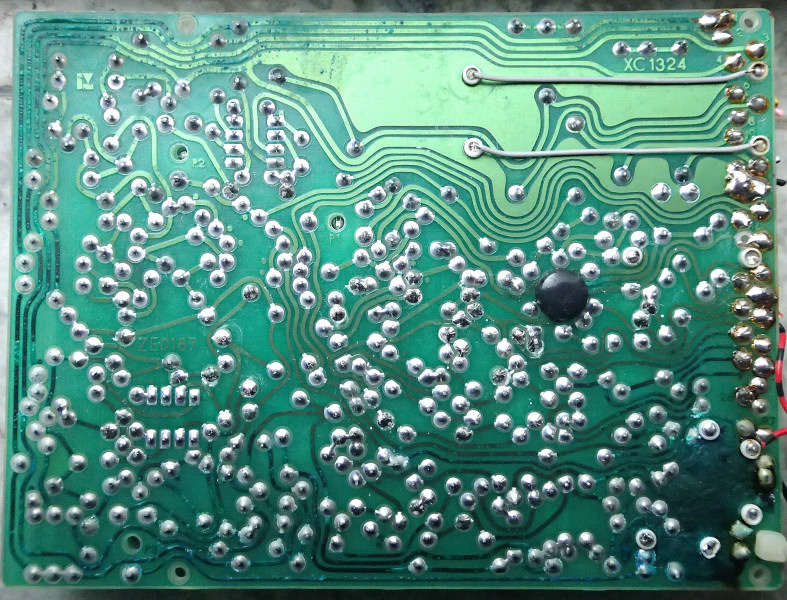

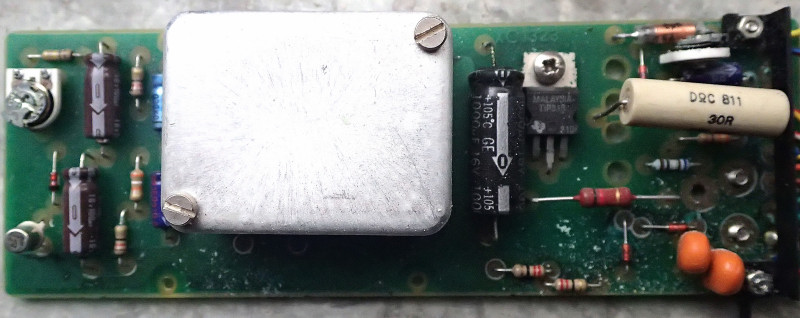

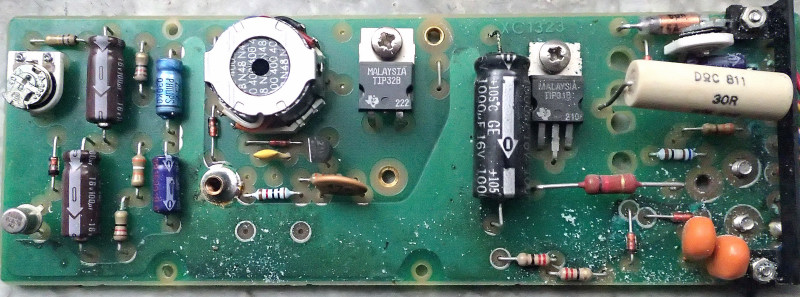

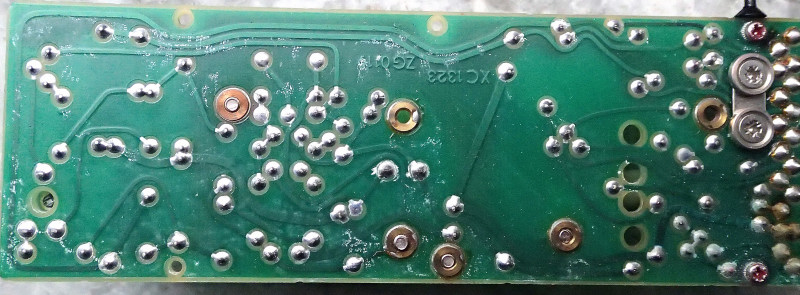

The 2635 is a four stage amplifier consisting of an input amplifier, lowpass filter-amplifier, integrator amplifier, and output amplifier. An overload detector, test oscillatorand power supply unit are also included.

The input signal is fed to the amplifier via either a miniature coaxial socket on the front panel or a BNC socket on the rear panel. The charge amplifier input eliminates the reduction in transducer sensitivity due to the use of long connecting cables and makes recalibration of the system unnecessary when changing to cables of different length.

Where transducers with a high temperature transient sensitivity are used, the high-pass filter in the input of the 2635 can be switched from 0.1 Hz to 1 Hz (−3 dB) in order to reduce interference from signals originating from low frequency temperature fluctuations.

The overall gain of the 2635 is adjusted in the input and integrator amplifiers in order to provide a rated output level switchable between 0.1 mV/unit and 1 V/unit in 10 dB steps. With these nine positions, the output signal level can be adjusted to best utilize the limited dynamic range of tape recorders and to match the various input requirements of recorders, voltmeters, analyzers, etc.

Low-pass Filter

Six switchable upper cut-off frequencies are provided by the low-pass filter, which is placed immediately after the input amplifier in order to filter out unwanted signal components before further amplification. The filter is a two-pole active circuit with a 12 dB/octave cut-off, which is particularly valuable when measuring vibration on rotating, geared machinery.

In this case, frequency components above the band of interest can have significantly higher levels than the measured signals. If these high frequency components are not filtered out at this stage, they can be clipped by amplifier overload and create difference frequencies which lie in the band of interest.

The special low-pass filter to limit the frequency range to 100 Hz (−10%) is used when recording vibration signals on tape for subsequent analysis in accordance with ISO 2631 (Guide for the evaluation of human exposure to whole-body vibration). These measurements are performed on passenger vehicles, tractors, and other machines where the human body as a whole is subjected to vibration.

The upper frequency limit of 200 kHz (−3 dB) is provided for underwater sound measurements with hydrophones.

Integrator–Amplifier

This amplifier has three switchable modes of operation, linear (acceleration), single integration (velocity), and double integration (displacement).

To suppress low frequency noise, the amplifier also provides low frequency cut-off, switchable to either 1 or 10 Hz (−10%) in the velocity and displacement modes.

The low frequency limit is extended down to 0.1 Hz (−3 dB) in the linear mode to take advantage of the very low temperature transient sensitivity of Brüel & Kjær’s Delta Shear accelerometers and force transducers at these low frequencies.

Output Amplifier

The short-circuit protected output amplifier provides a low impedance signal to a BNC socket on the rear

panel. The output amplifier features a three-digit sensitivity adjustment network which enables the 2635 to be conditioned to suit transducer sensitivities between 0.1 and 11 pC/unit. This feature greatly simplifies the calibration and reading of a measuring system, especially when using transducers which have “odd” sensitivity values (non Uni-Gain types).

It should be noted that the transducer conditioning and sensitivity adjustment is optimised for metric units throughout. However, an accelerometer sensitivity expressed in pC/g can be dialled into the 2635 to give calibrated output in terms of g instead of ms-2.

The overlay SC 0418 can be stuck onto the front of the 2635 to simplify the subsequent calibration of the measurement chain.

Overload Detector Overload is indicated by an LED on the front panel. The overload detector monitors an overload condition at the input amplifier, low-pass filter, and at the output amplifier. In this way, overloads in various parts of the circuit are not masked by filtering.

Test Oscillator The 2635 is equipped with a pushbutton activated test oscillator which applies a 159 Hz sinusoidal signal to the input. The test frequency of 159 Hz is chosen to simplify checking in the velocity and displacement modes. At this frequency, the output in velocity and displacement modes should be respectively 20 and 40 dB lower than the output in acceleration mode. See the frequency response in Fig. 3. The oscillator level is factoryadjusted to give an output level of 1 V RMS (for the prescribed sensitivity settings), which is used in the calibration and setting up of recording levels on the Brüel & Kjær portable tape recorders.

Power Supply

The 2635 can be powered in three ways:

- Three standard 1.5 V batteries (IEC Type R 20) are housed inside the cabinet. With standard batteries, the normal lifetime with intermittent use is approximately 100 hours. These can be replaced by rechargeable NiCd batteries. A built-in voltage limiter allows the use of ordinary 12 V battery chargers, for example Brüel & Kjær’s ZG 0283. Battery condition is displayed by an indicator on the front panel.

- An external +6 V to +28 V single polarity power supply may be used. When the 2635 is used in conjunction with a Brüel & Kjær measuring amplifier or frequency analyzer, the 12 V supply available at the preamplifier input socket can be connected to the “Ext. Power Input” socket on the 2635

- A regulated ±14 V power supply can be used to power the amplifiers directly, thus by-passing the DC converter

The recharging voltage, the +6 V to +28 V supply and the ±14 V supply are all applied through a 7 pin DIN socket on the rear panel.

![]() Bruel & Kjaer - Charge Amplifier 2635

Bruel & Kjaer - Charge Amplifier 2635