![]() Ammonium acryloyldimethyltaurate/VP copolymer

Ammonium acryloyldimethyltaurate/VP copolymer

Rating : 7.5

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

10 pts from CarPas

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.Evaluate | Where is this found? |

| " Ammonium acryloyldimethyltaurate/V" about Ammonium acryloyldimethyltaurate/VP copolymer Review Consensus 10 by CarPas (5242 pt) | 2022-May-06 11:55 |

| Read the full Tiiip | (Send your comment) |

Compendium of the most significant studies with reference to properties, intake, effects.

Velasco, M. V. R., Sarruf, F. D., Salgado-Santos, I. M. N., Haroutiounian-Filho, C. A., Kaneko, T. M., & Baby, A. R. (2008). Broad spectrum bioactive sunscreens. International journal of pharmaceutics, 363(1-2), 50-57.

Abstract. The objective of the present research work was to develop bioactive sunscreen delivery systems containing rutin, Passiflora incarnata L. and Plantago lanceolata extracts associated or not with organic and inorganic UV filters.

Pinto, C. A. S. D. O., Lopes, P. S., Sarruf, F. D., Polakiewicz, B., Kaneko, T. M., Baby, A. R., & Velasco, M. V. R. (2011). Comparative study of the stability of free and modified papain incorporated in topical formulations. Brazilian Journal of Pharmaceutical Sciences, 47(4), 751-760.

Abstract. Papain is an enzyme used in topical formulations as a proteolytic debriding agent for the treatment of open, extensive wounds and burnings. It is also employed as an enhancer for cutaneous permeation of active compounds, chemical peeling and as a progressive depilatory agent. The stability of formulations containing enzymes is not easy. In this research, papain was modified with polyethylene glycol in order to increase the stability of the formulations.

da Silva, A. C., Paiva, J. P., Diniz, R. R., Dos Anjos, V. M., Silva, A. B. S., Pinto, A. V., ... & Santos, B. A. M. (2019). Photoprotection assessment of olive (Olea europaea L.) leaves extract standardized to oleuropein: In vitro and in silico approach for improved sunscreens. Journal of Photochemistry and Photobiology B: Biology, 193, 162-171.

Abstract. This study was designed to investigate the photoprotective potential of olive leaves extract standardized for oleuropein performing a set of in vitro and in silico tools as an innovative approach, highlighting yeast assays, in vitro Sun Protection Factor (SPF) and molecular modelling studies of UV absorption.

Fernandes, É. M., de Brito Damasceno, G. A., Ferrari, M., & de Azevedo, E. P. (2015). Incremento na dissolução da caffeine em base de ammonium acryloyldimethyltaurate/vp copolymer: desenvolvimento farmacotécnico de géis anti-celulite. Revista de Ciências Farmacêuticas Básica e Aplicada, 36(1).

Abstract. A hidrolipodistrofia ginóide (HLDG), popularmente conhecida como “celulite”, consiste em uma alteração patológica do tecido adiposo e da função venolinfática. Géis contendo caffeine tem sido empregados no tratamento não-invasivo da HLDG, oferecendo resultados satisfatórios a baixos custos. Devido a baixa hidrossolubilidade da caffeine, este gel apresenta como principal inconveniente a formação de precipitados/ grumos, oriundos da precipitação da caffeine na base hidrofílica (gel). Este trabalho tem como objetivo o incremento na dissolução da caffeine em gel de Ammonium Acryloyldimethyltaurate/VP Copolymer, através da adição de adjuvantes como o citric acid e o sodium benzoate, além de solução hidroalcoólica, empregada como co-solvente da caffeine.

Isaac, V. L. B., Cefali, L. C., Chiari, B. G., Almeida, M. G. J., Ribeiro, H. M., & Correa, M. A. (2013). Effect of various thickening agents on the rheological properties of oil-in-water emulsions containing nonionic emulsifier. Journal of dispersion science and technology, 34(6), 880-885.

Abstract. The knowledge of rheological characteristics can indicate the emulsions properties, thus, nowadays rheology is used in the cosmetic and pharmaceutical industries, even to study the influence of rheological additives on them.

Nigro, F., Cerqueira, C., Rossi, A., Cardoso, V., Vermelho, A. B., Ricci-Júnior, E., ... & Mansur, C. R. E. (2020). Development, characterization and in vitro toxicity evaluation of nanoemulsion-loaded hydrogel based on copaiba oil and coenzyme Q10. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 586, 124132.

Abstract. In this work, we used copaiba oil, a vegetable oil with properties similar to those of CQ10, to compose oil-in-water (O/W) nanoemulsions with CQ10 (NECQ10) and without it (NECO), for comparative purposes, prepared by ultrasound processing.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

| "Descrizione" about Ammonium acryloyldimethyltaurate/VP copolymer Review Consensus 10 by CarPas (5242 pt) | 2024-Oct-11 19:51 |

| Read the full Tiiip | (Send your comment) |

Ammonium acryloyldimethyltaurate/VP copolymer is a synthetic polymer with a vinylpyrrolidone copolymer made from partially neutralised polysulphonic acid, a synthetic polymer primarily used as a thickening, stabilizing, and emulsifying agent in cosmetic formulations. This copolymer is created by polymerizing ammonium acryloyldimethyltaurate with vinylpyrrolidone (VP), and is valued for its ability to form stable, lightweight, and transparent gels. It is commonly found in skincare products like moisturizers and lotions, and in hair care products like gels and conditioners.

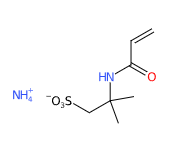

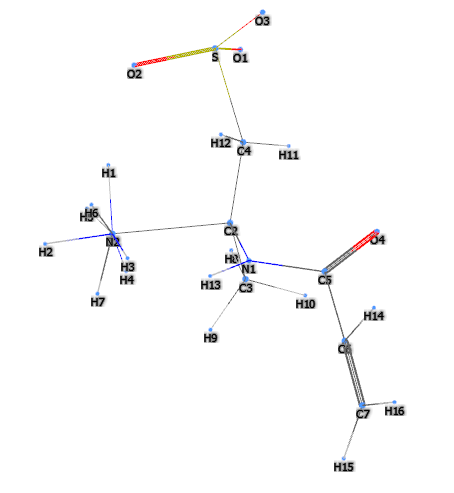

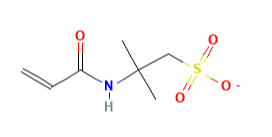

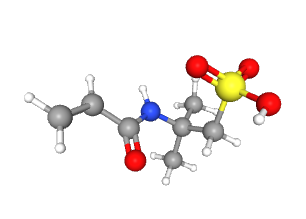

Chemical Composition and Structure

The Ammonium Acryloyldimethyltaurate/VP copolymer consists of two key components: ammonium acryloyldimethyltaurate, which provides water solubility and thickening properties, and vinylpyrrolidone (VP), which adds elasticity and the ability to form lightweight films. This combination results in a stable and versatile polymer suitable for a wide range of cosmetic formulations.

The name defines the structure of the molecule:

- Ammonium acryloyldimethyltaurate is a monomer derived from acrylic acid, to which is bonded an ammonium salt of a dimethyltaurate, which is a compound derived from taurine.

- VP stands for vinylpyrrolidone, another monomer used in the formation of the copolymer. Vinylpyrrolidone is a vinyl compound that contains a carbon-carbon double bond with a pyrrolidic group (a five-membered ring containing nitrogen).

- Copolymer indicates that the polymer is composed of more than one type of monomer, in this case Ammonium acryloyldimethyltaurate and vinylpyrrolidone.

Ammonium Acryloyldimethyltaurate/VP Copolymer, Description of the raw materials used in its production:

- Acryloyldimethyl Taurate Monomer is a water-soluble monomer derived from taurine, an amino acid.

- Vinylpyrrolidone (VP) Monomer - An organic monomer that's water-soluble.

Production Process

The Ammonium Acryloyldimethyltaurate/VP copolymer is produced through the polymerization of ammonium acryloyldimethyltaurate with vinylpyrrolidone. This controlled polymerization process results in a stable and safe product suitable for various cosmetic applications.

Step-by-step summary of its industrial chemical synthesis process.

Preparation of Components: The main ingredients include acryloyldimethyltauric acid and vinyl pyrrolidone (VP). These components are weighed and prepared for the reaction.

Polymerization: Acryloyldimethyltauric acid and vinyl pyrrolidone are polymerized together in the presence of an initiator, usually a peroxide, to initiate the polymerization reaction. This process occurs by heating the materials in a chemical reactor, where the monomers bond to form a polymer network.

Neutralization: After polymerization, the mixture is neutralized with ammonia to obtain the ammonium salt of the copolymer. This step is essential to ensure that the copolymer has the desired properties.

Purification: The produced ammonium acryloyldimethyltaurate/VP copolymer is purified to remove any impurities and chemical residues. This may include filtration and washing processes to ensure a high-quality product.

Quality Control and Packaging: Finally, the copolymer undergoes quality control checks to verify its purity and functional properties. After analysis, it is packaged for distribution and use in cosmetic and skincare products.

Physical Properties

The copolymer typically appears as a fine powder or clear gel. It is water-soluble and can form stable, viscoelastic gels. It is particularly effective at enhancing the texture of cosmetic products, providing a silky, smooth feel without stickiness. Due to its lightweight nature, it is ideal for products that require a non-greasy, lightweight feel on the skin and hair.

What it is used for and where

Medical

Biocompatible and haemocompatible, it can be used with sufficient stability as a cardiovascular implant coating for endothelial cell antibody applications in various biological systems in the surface modification of cardiovascular stents (1).

To maintain the physical properties of dental enamel after bleaching, Ammonium acryloyldimethyltaurate/VP copolymer has proved to be a promising agent when used in combination with carbamide (2).

Cosmetics

Film-forming, thickening and stabilising agent in cosmetic formulas with a pleasant skin feel.

Viscosity control agent. It controls and adapts viscosity to the required level for optimal chemical and physical stability of the product and dosage in gels, suspensions, emulsions, solutions.

Use: 0.5 ~ 1.2%

Commercial applications

Gelling Agents. This copolymer is often used to increase the viscosity of formulations, giving products a gel-like consistency.

Stabilizer. It helps to stabilize emulsions, preventing the separation of water-based and oil-based components.

Skin Products. Found in creams, lotions, and serums for its ability to form a thin film on the skin, providing a smooth and silky feel.

Hair Products: Used in conditioners, hair gels, and other hair products to enhance texture and distribution.

Cosmetics. Can be present in foundations, primers, and other cosmetic products to enhance their consistency and performance.

Health and Safety Considerations

Safety in Use

The Ammonium Acryloyldimethyltaurate/VP copolymer is considered safe for use in cosmetic products. It is generally well tolerated by the skin and hair, and does not cause irritation or sensitization when used at recommended concentrations.

Allergic Reactions

Allergic reactions to this ingredient are very rare, but as with any cosmetic ingredient, irritation may occur in individuals with particularly sensitive skin.

Toxicity and Carcinogenicity

It has been evaluated by major regulatory authorities and is considered safe for use in cosmetic products.

Environmental Considerations

As a synthetic polymer, the biodegradability of the Ammonium Acryloyldimethyltaurate/VP copolymer is limited. However, its use in small, controlled amounts in cosmetic products does not pose a significant environmental risk if properly disposed of.

Regulatory Status

The Ammonium Acryloyldimethyltaurate/VP copolymer is approved for use in cosmetics by major regulatory authorities, including the European Union and the Food and Drug Administration (FDA) in the United States.

For more information:

Ammonium acryloyldimethyltaurate/VP copolymer studies

| Appearance | White powder |

| Content | 92% min |

| Water | 7% max |

| pH | 4.0~6.0 |

| Viscosity | 48000~80000 mpas |

| PSA | 98.58000 |

| LogP | 2.20000 |

|  |

|  |

- Molecular Formula C7H16N2O4S

- Molecular Weight 224.28

- Exact mass 224.08300

- CAS 58374-69-9

- UNII KBC00G95HI

- EC Number 611-646-3

- DSSTox Substance ID DTXSID60886261

- IUPAC azanium;2-methyl-2-(prop-2-enoylamino)propane-1-sulfonate

- InChI=1S/C7H13NO4S.H3N/c1-4-6(9)8-7(2,3)5-13(10,11)12;/h4H,1,5H2,2-3H3,(H,8,9)(H,10,11,12);1H3

- InChl Key BQMNFPBUAQPINY-UHFFFAOYSA-N

- SMILES CC(C)(CS(=O)(=O)[O-])NC(=O)C=C.[NH4+]

- MDL number

- PubChem Substance ID

Synonyms

- Aristoflex® AVC

- 1-Propanesulfonic acid, 2-methyl-2-[(1-oxo-2-propen-1-yl)amino]-, ammonium salt (1:1)

- Lubrizol 2411

- 2-acrylamido-2-methyl-1-propanesulfonic acid-ammonium salt

- azanium,2-methyl-2-(prop-2-enoylamino)propane-1-sulfonate

References_______________________________________________________________________

(1) Sareło P, Duda M, Gąsior-Głogowska M, Wysokińska E, Kałas W, Podbielska H, Wawrzyńska M, Kopaczyńska M. Antibody CD133 Biofunctionalization of Ammonium Acryloyldimethyltaurate and Vinylpyrrolidone Co-Polymer-Based Coating of the Vascular Implants. Materials (Basel). 2020 Dec 10;13(24):5634. doi: 10.3390/ma13245634.

(2) Gouveia THN, de Souza DFS, Aguiar FHB, Ambrosano GMB, Lima DANL. Effect of ammonium acryloyldimethyltaurate copolymer on the physical and chemical properties of bleached dental enamel. Clin Oral Investig. 2020 Aug;24(8):2701-2711. doi: 10.1007/s00784-019-03132-3.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

Read other Tiiips about this object in __Italiano (2)

Component type: Chemical Main substances:

Last update: 2022-05-06 11:59:03 | Chemical Risk: |