Check the ingredients!

... live healthy!

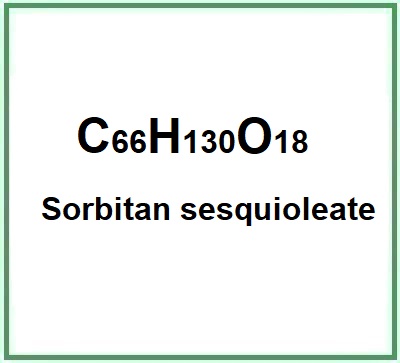

![]() Sorbitan sesquioleate

Sorbitan sesquioleate

Rating : 7

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

10 pts from Whiz35

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.Evaluate | Where is this found? |

| "Descrizione" about Sorbitan sesquioleate Review Consensus 10 by Whiz35 (11828 pt) | 2023-Dec-03 20:39 |

| Read the full Tiiip | (Send your comment) |

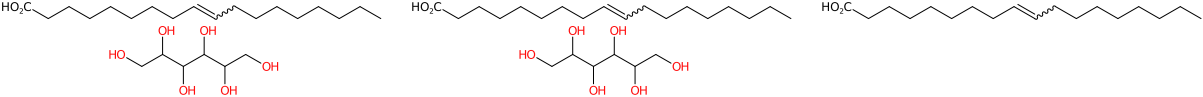

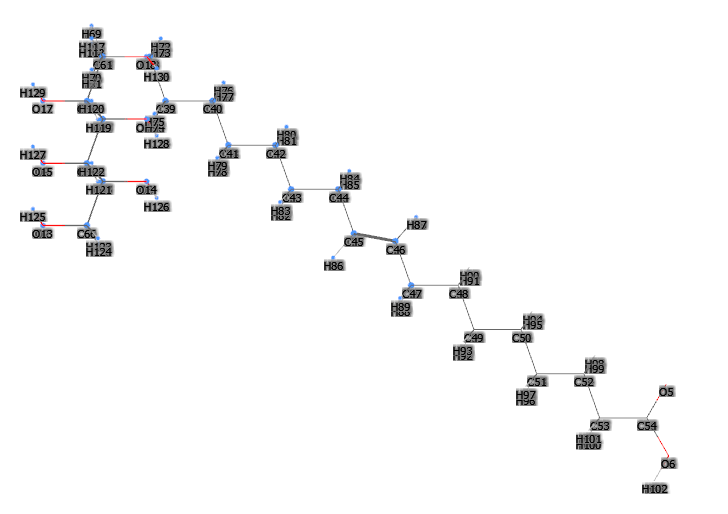

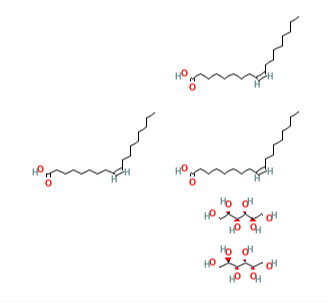

Sorbitan sesquioleate (SSO) is a chemical compound obtained synthetically by the esterification of sorbitan (dehydrated sorbitol) with fatty acids. The fatty acids used to synthesise sorbitan esters generally include, palmitic acid, lauric acid, oleic acid and stearic acid. The esterification process involves a reaction between an alcohol, in this case sorbitol, and a carboxylic acid, oleic acid, to produce the ester Sorbitan sesquioleate.

It appears as a viscous yellowish liquid that is slightly soluble in ethanol, ethyl acetate, in fatty and mineral oils, petroleum and toluene, and dispersible in water. Insoluble in cold and hot water.

What it is used for and where

Cosmetics

Sorbitan esters are non-ionic lipophilic surfactants that are commonly used as emulsifiers and stabilisers in the formulation of cosmetic creams.

Surfactant - Emulsifying agent. Emulsions are thermodynamically unstable and are used to soothe or soften the skin and emulsify, so they need a specific, stabilising ingredient. This ingredient forms a film, lowers the surface tension and makes two immiscible liquids miscible. A very important factor affecting the stability of the emulsion is the amount of the emulsifying agent. Emulsifiers have the property of reducing the oil/water or water/oil interfacial tension, improving the stability of the emulsion and also directly influencing the stability, sensory properties and surface tension of sunscreens by modulating the filmometric performance.

Emulsifier in water/oil solutions with a value of 3.7 HLB. Generally, the hydrophilic-lipophilic balance (HLB) range is between 1.6 - 8.6, which makes them dissolvable in polar organic solvents and oils.

Food

Sorbitan sesquioleate functions as an emulsifier in food products. Emulsifiers have the property of directly influencing the stability, sensory properties and surface tension of sunscreens by modulating their filmometric performance.

Other Uses

Co-solvent and anti-rust agent for petroleum and oil.

Applications

Safety

Sorbitan sesquioleate has a modest allergy index. A study by the Cosmetic Ingredient Review Expert panel was credited with an allergy rate of less than 1% (1).

Typical commercial product characteristics Sorbitan sesquioleate

| Appearance | Viscous Liquid Pale Yellow or Brown |

| Boiling Point | 738.7ºC at 760 mmHg |

| Flash Point | 205.1ºC |

| Density | 0.993g/cm3 0.989 g/mL at 25 °C(lit.) |

| PSA | 292.20000 |

| LogP | 13.24590 |

| Refraction Index | 1.493 |

| Vapor Pressure | 0.81 psi ( 20 °C) |

| Acid value | 8.5 mgKOH/g |

| Hydroxyl value | 188 mgKOH/g |

| Saponification Value | 149 mgKOH/g |

| Water Content | ≤ 1 % |

| Viscosity | 1500 mPa.s |

Synonyms

References______________________________________________________________________

(1) Lanigan RS, Yamarik TA; Cosmetic Ingredient Review Expert panel. Final report on the safety assessment of sorbitan caprylate, sorbitan cocoate, sorbitan diisostearate, sorbitan dioleate, sorbitan distearate, sorbitan isostearate, sorbitan olivate, sorbitan sesquiisostearate, sorbitan sesquistearate, and sorbitan triisostearate. Int J Toxicol. 2002;21 Suppl 1:93-112. doi: 10.1080/10915810290096414.

Abstract. Sorbitan fatty acid esters are mono-, di-, and triesters of fatty acids and sorbitol-derived hexitol anhydrides. They function as surfactants in cosmetic formulations. Previously, the Cosmetic Ingredient Review (CIR) Expert Panel had reviewed the safety of several of these sorbitan fatty acid esters (Sorbitan Laurate, Sorbitan Oleate, Sorbitan Palmitate, Sorbitan Sesquioleate, Sorbitan Stearate, Sorbitan Trioleate, and Sorbitan Tristearate). This safety assessment is an addendum to that report that includes Sorbitan Caprylate, Sorbitan Cocoate, Sorbitan Diisostearate, Sorbitan Dioleate, Sorbitan Distearate, Sorbitan Isostearate, Sorbitan Olivate, Sorbitan Sesquiisostearate, Sorbitan Sesquistearate, and Sorbitan Triisostearate. Although concentrations of these ingredients up to 25% have been reported to be used, most commonly they are used at less than 10%. These esters may be hydrolyzed to the fatty acid and anhydrides of Sorbitol. Fatty Acids are absorbed and metabolized. Sorbitan fatty acid esters were relatively nontoxic via ingestion in acute and long-term studies. They were generally minimal to mild skin irritants in animal studies, except that Sorbitan Isostearate applied to the skin was a moderate irritant in one rabbit study and when injected intradermally caused mild to severe irritation in guinea pigs. Sorbitan fatty acid esters did not sensitize guinea pigs. The fatty acid component, tested alone, typically caused only slight irritation and sensitization, and was not photosensitizing. Sorbitan fatty acid esters were not ocular irritants. Fatty acids are normal components of diet for which no data were available concerning reproductive or developmental toxicity, but Sorbitol had no adverse effects on the reproduction of CD rats during a multigeneration feeding study and was not a reproductive toxin at doses of 3000 to 7000 mg/kg/day for 2 years. Overall these esters and their corresponding fatty acids were not mutagenic, but Sorbitan Oleate was reported to reduce DNA repair following ultraviolet radiation exposure in human lymphocytes in culture. Sorbitan Laurate and Sorbitan Trioleate were cocarcinogens in one mouse study, but Sorbitan Trioleate and Sorbitan Oleate were not tumor promoters in another study. In clinical tests, Sorbitan fatty acid esters were generally minimal to mild skin irritants and were nonsensitizing, but Sorbitan Sesquioleate did produce an allergic reaction in fewer than 1% of patients with suspected contact dermatitis and addition of Sorbitan Sesquioleate to the components of a fragrance mix used in patch testing increased both irritant and allergic reactions to the fragrance mix. Careful consideration was made of the data on the cocarcinogenesis of Sorbitan Laurate and Sorbitan Trioleate, but the high exposure levels, high frequency of exposure, and absence of a dose-response led to the conclusion that there was not a cocarcinogenesis risk with the use of these ingredients in cosmetic formulations. Accordingly, these ingredients were considered safe for use in cosmetic formulations under the present practices of use.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

| "Sorbitan sesquioleate studies" about Sorbitan sesquioleate Review Consensus 10 by Whiz35 (11828 pt) | 2022-Sep-25 18:00 |

| Read the full Tiiip | (Send your comment) |

Compendium of the most significant studies with reference to properties, intake, effects.

Fiume, M. M., Bergfeld, W. F., Belsito, D. V., Hill, R. A., Klaassen, C. D., Liebler, D. C., ... & Heldreth, B. (2019). Safety assessment of Sorbitan esters as used in cosmetics. International journal of toxicology, 38(2_suppl), 60S-80S.

Abstract. The Cosmetic Ingredient Review Expert Panel (Panel) assessed the safety of 20 sorbitan esters; this report included sorbitan esters that were reviewed in 1985 and 2002, as well as 3 previously unreviewed sorbitan esters (sorbitan undecylenate, sorbitan sesquicaprylate, and sorbitan palmate). Most of the sorbitan esters are reported to function in cosmetics as surfactant-emulsifying agents. The Panel reviewed the data from previous sorbitan ester reports, as well as additional data included in this report, to determine the safety of these ingredients. The Panel concluded that the sorbitan esters included in this safety assessment are safe in cosmetics in the present practices of use and concentration.

de Groot A, Gilissen L, Geier J, Orton D, Goossens A. Adding sorbitan sesquioleate to the European baseline series: Necessary, reasonable, or unavoidable? Contact Dermatitis. 2019 Sep;81(3):221-225. doi: 10.1111/cod.13332.

Abstract. Positive reactions to fragrance mix I (FM I) are frequent in consecutively patch tested patients suspected of having allergic contact dermatitis. However, the FM I test preparations contain 5% of the emulsifier sorbitan sesquioleate (SSO), and it is well known that SSO can cause contact allergic reactions in its own right. ...© 2019 John Wiley & Sons A/S.

Frosch PJ, Pilz B, Burrows D, Camarasa JG, Lachapelle JM, Lahti A, Menné T, Wilkinson JD. Testing with fragrance mix. Is the addition of sorbitan sesquioleate to the constituents useful? Contact Dermatitis. 1995 May;32(5):266-72. doi: 10.1111/j.1600-0536.1995.tb00779.x.

Abstract. In a multicentre study, the value of adding sorbitan sesquioleate (SSO) to the constituents of the 8% fragrance mix (FM) was investigated. In 7 centres, 709 consecutive patients were tested with 2 types of FM from different sources, its 8 constituents with 1% SSO, its 8 constituents without SSO, and 20% SSO. 5 patients (0.71%) reacted to the emulsifier SSO itself, read as definitely allergic on day 3/4. 53 patients reacted to either one of the mixes with an allergic type of reaction....

Lee, Y. Y., & Yoon, K. S. (2020). Determination of required HLB values for Citrus unshiu fruit oil, Citrus unshiu peel oil, Horse Fat and Camellia japonica seed oil. J Cosmet Sci, 71, 411-424.

Abstract. … X: sorbitan sesquioleate (HLB = 3.70) + polysorbate 60 (HLB = 14.90)] was … HLB value, the more the upper part is separated. Figures 2 and 3 show that the highest turbidity when HLB …

Nilkumhang S, Basit AW. The robustness and flexibility of an emulsion solvent evaporation method to prepare pH-responsive microparticles. Int J Pharm. 2009 Jul 30;377(1-2):135-41. doi: 10.1016/j.ijpharm.2009.03.024.

Abstract. A microparticle preparation method based on an emulsion of ethanol in liquid paraffin stabilised using sorbitan sesquioleate which produces enteric microparticles of excellent morphology, size and pH-sensitive drug release was assessed for its robustness to changes in formulation and processing parameters. Prednisolone and methacrylic acid and methyl methacrylate copolymer (Eudragit S) were the drug and polymer of choice. Emulsion solvent evaporation procedures are notoriously sensitive to changes in methodology and so emulsion stirring speed, drug loading, polymer concentration and surfactant (emulsifier) concentration were varied; microparticle size, encapsulation efficiency, yield and in vitro dissolution behaviour were assessed. The yield and encapsulation efficiency remained high under all stirring speeds, drug loadings and polymer concentrations. This suggests that the process is flexible and efficiency can be maintained. Surfactant concentration was an important parameter; above an optimum concentration resulted in poorly formed particles. All processing parameters affected particle size but this did not alter the acid resistance of the microparticles. At high pH values the smaller microparticles had the most rapid drug release. In conclusion, the microparticle preparation method was resistant to many changes in processing, although surfactant concentration was critical. Manipulation of particle size can be used to modify the drug release profiles without adversely affecting the gastro-resistant properties of these pH-responsive microparticles.

Coffin, M. D. (1992). The development and physical-chemical properties of biodegradable pseudolatexes and their application to sustained release drug delivery systems.

Abstract. … sorbitan sesquioleate. The utility of Pluronic F-68$\sp\circler$ was dependent upon its solubility in the organic solvent which was used to dissolve the polymers. The chemical …

Kaneko, H., & Hirota, S. (1985). Effects of particle size and stabilizing agents upon dielectric properties of water-in-oil type emulsions. Chemical and pharmaceutical bulletin, 33(12), 5484-5494.

Abstract. The dielectric relaxation due to the interfacial polarization of water-in-oil type emulsions (W/O emulsions) was investigated at frequencies ranging from 10 kHz to 3 MHz. In preparing W/O emulsions, differences of mixing or micronizing efficiency arise between bench-scale and production-scale apparatus owing to the difference of mixing or shear rate. Therefore, the size of dispersed particles can be regarded as an index of the mechanical effect arising from the mixing apparatus. Firstly, the relationship between the size of dispersed particles and the dielectric properties of W/O emulsions was investigated. It was found that 1 d after preparation, the degree of particle aggregation leveled off and became fairly steady, and the values, for W/O emulsions with coarse particles, of the limiting dielectric constant at low frequency, εl, and parameter α, indicating the distribution of relaxation frequencies, determined from complex plane plots, were greater than for those for emulsions with fine particles. The value of εl is thought to be related to the thickness of the surfactant layer between aggregated particles rather than to the size of particle clusters, but the relation becomes more ambiguous as the concentration of surfactant becomes higher. Relaxation frequency, f0, decreases with increasing particle aggregation. Secondly, in order to obtain good emulsification in the W/O emulsion, the stabilizing effects of 23 stabilizing agents upon the state of dispersion of W/O emulsion were evaluated by dielectric measurement. Primary emulsifiers for micronizing dispersed particles, such as polyoxyethylene (POE) (6) sorbitan monooleate, secondary emulsifiers for protecting interface membranes, such as phytosterol, and lipojelling additives, such as aluminum stearate, decreased the value of εl of W/O emulsions. From the present study, it was concluded that dielectric evaluation can be applied to examine the mechanical effects on emulsification and to as an aid in the selection of optimum additives and vehicles for a W/O emulsion.

Constantinides, P. P., & Scalart, J. P. (1997). Formulation and physical characterization of water-in-oil microemulsions containing long-versus medium-chain glycerides. International journal of pharmaceutics, 158(1), 57-68.

Abstract. Stable self-emulsifying water-in-oil (w/o) microemulsions of extremely small particle size (5–30 nm) and consisting of an oil, a blend of a low and high HLB surfactants and an aqueous phase, have been developed using commercially available and pharmaceutically acceptable components. Their formation was monitored by the corresponding pseudo-ternary phase diagram....

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

Read other Tiiips about this object in __Italiano (2)

Component type: Chemical Main substances:

Last update: 2022-09-25 16:42:36 | Chemical Risk: |