Compendium of the most significant studies with reference to properties, intake, effects.

Belsito, M. D., Klaassen, C. D., Liebler, D. C., Marks Jr, J. G., & Peterson, L. A. (2019). Safety Assessment of Caprylhydroxamic Acid as Used in Cosmetics.

Abstract. Enclosed is the Draft Tentative Report of the Safety Assessment of Caprylhydroxamic Acid as Used in Cosmetics. (It is identified in this report package as caphyd122019rep.) At the June 2019 meeting, the Panel found that the data were insufficient to determine safety. Several human repeated insult patch tests (HRIPTs) were included in the Draft Report that described testing with varying concentrations of Caprylhydroxamic Acid. Although the test results are largely negative, there were some alerts for sensitization in HRIPTs on formulations containing less than the maximum reported use concentration of Caprylhydroxamic Acid. Because the potential for sensitization could not be ruled out completely based on the reactions observed in the HRIPTs, and because of the reported reactions to Caprylhydroxamic Acid in a reformulated moisturizer in Finland and the absence of a local lymph node assay or guinea pig maximization test to demonstrate a lack of sensitization potential,...

CHANDLER, M., & O’LENICK, T. O. N. Y. (2019). Inverting the tables on emulsion sensory and performance. Household and Personal care Today, 14(2), 22-25.

Abstract. For oil in water (O/W) emulsions, Appearance, Pick-up, and Rub-out (APR) aesthetic characteristics are all dictated by emulsifier selection; in After�feel evaluations, there is an equal influence of emulsifier and emollient(1). This was all laid out elegantly by Dr. Johann Wiechers and the team back in 2002. This current study demonstrates that invert (water-in-oil and water-in-silicone) emulsions made with PEG-free TMP Lauryl Dimethicone emulsifier had different aesthetic characteristics when compared to the same emulsions using the very similar Lauryl PEG-8 Dimethicone emulsifier. Overall, it was demonstrated that invert (water-in-oil) emulsions have similar properties from their oil-in-water counterparts in terms of APR and After�feel characteristics but the emulsion characteristics are also effected by the emollient in an invert emulsion.This study was undertaken by Siltech and ACT Technologies and was presented by Mark Chandler of ACT Technologies at the IPCE in 2018 in Italy

Godbille‐Cardona, G., Nicell, J. A., Marić, M., & Leask, R. L. Succinate‐based plasticizers: Effect of plasticizer structure on the mechanical and thermal performance of poly (vinyl chloride) plastic formulations. Journal of Vinyl and Additive Technology.

Abstract. A new family of succinate-based plasticizers, consisting of molecules with a linear alkyl chain capped with n-alkyl succinates on both ends, was evaluated as potential bio-based plasticizers for stiff polymers. The influence of the central and side alkyl chain lengths on the mechanical and thermal properties as well as the migration behavior of poly(vinyl chloride) (PVC)/plasticizer blends was evaluated. The central chain length had the greatest influence on plasticizer performance, with shorter chains leading to blends with higher stress at break and surface hardness, whereas long chains produced softer blends. An optimum chain central length of five carbon atoms was observed, with longer chains leading to reduced compatibility and exudation of the plasticizer at higher plasticizer concentrations. The entire family of plasticizers performed comparably or better than the commercial plasticizer di(2-ethylhexyl) phthalate (DEHP) when incorporated into the blend at concentrations of 20–60 parts per hundred resin (phr). Overall, the succinate-based plasticizers/PVC blends all exhibited equal or improved tensile properties (by up to 77%), surface hardness (reduced by up to 43%), glass transition temperature (reduced by up to 11°C), and migration into organic media (reduced by up to 38%) when compared with blends with DEHP at 40 phr.

Jamarani, R., Halloran, M. W., Panchal, K., Garcia‐Valdez, O., Mafi, R., Nicell, J. A., ... & Marić, M. (2021). Additives to prevent the formation of surface defects during poly (vinyl chloride) calendering. Polymer Engineering & Science, 61(4), 1209-1219.

Abstract. Gas checks are visible fleck-shaped defects that occur on the surface of poly(vinyl chloride) (PVC) films during industrial calendering. Films containing these surface defects often do not meet minimum product specifications and therefore must be disposed of or recycled, resulting in increased cost and material waste. Currently, gas checks are controlled by keeping film gauge low and through trial-and-error modifications of processing parameters by calender operators. In this work, our group developed a series of chemical additives that can be blended with PVC to prevent the formation of gas check defects. We found that a series of poly(caprolactone) (PCL)-based compounds with diester linkers and alkyl chain cappers were all effective at preventing the formation of gas checks during calendering, with additive concentrations as low as 8 phr producing films with no gas checks. We found that the blends produced with our additives had higher melt viscosities than those produced with additives that do not remove gas checks, suggesting that viscosity plays an important role in preventing gas check defects.

European Commission (2003) Technical Guidance Document on Risk Assessment in Support of Commission Directive 93/67/EEC on Risk Assessment for New Notified Substances and Commission Regulation (EC) No 1488/94 on Risk Assessment for Existing Substances and Directive 98/8/EC of the European Parliament and of the Council Concerning the Placing of Biocidal Products on the Market – Part I. Institute for Health and Consumer protection, European Chemicals Bureau, European Communities.

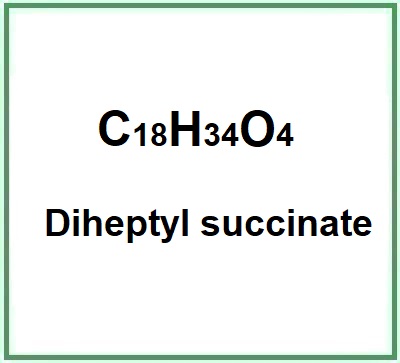

![]() Diheptyl succinate

Diheptyl succinate