![]() Glyceryl oleate

Glyceryl oleate

Rating : 7

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

10 pts from Ark90

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.Evaluate | Where is this found? |

| "Descrizione" about Glyceryl oleate Review Consensus 10 by Ark90 (12432 pt) | 2023-Dec-13 11:04 |

| Read the full Tiiip | (Send your comment) |

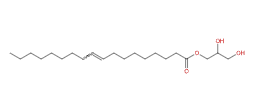

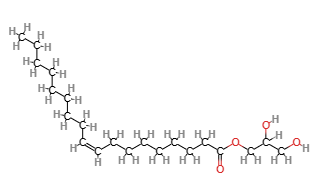

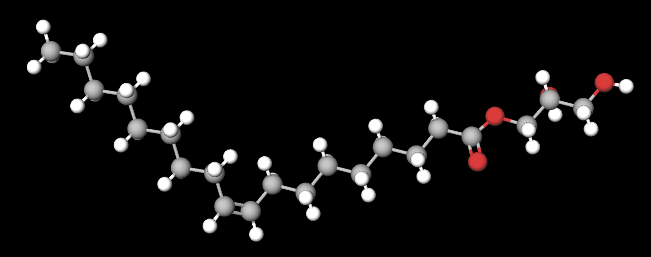

Glyceryl Oleate (Glyceryl monooleate) is an intermediate chemical compound prepared by the esterification of oleic acid, monoglyceric monoester obtained by the esterification of glycerine and carboxylic acids (an equivalent of a carboxylic acid and an equivalent of glycerine), in this ingredient the oleic acid.

It contains glyceryl esters of fatty acids found in oleic acid.

Name breakdown and function of the components

- Glyceryl - Refers to the glycerin part of the molecule. Glycerin is a tri-valent alcohol compound derived from the saponification of oils.

- Oleate - Refers to the salt or ester of oleic acid, a monounsaturated fatty acid found mainly in vegetable oils such as olive oil.

Description and function of the raw materials used in production

- Glycerin - A humectant compound that helps retain moisture in the skin.

- Oleic acid - A monounsaturated fatty acid derived from vegetable oils.

Summary of the industrial synthesis process step by step

- Reaction - Glycerin reacts with oleic acid in the presence of an acid catalyst to form the ester, glyceryl oleate.

- Purification - After the reaction, the reaction mixture undergoes various purification processes to remove impurities and excess catalysts.

- Isolation - Pure glyceryl oleate is then isolated and collected as the final product.

It appears as a transparent to straw yellow liquid.

What it is used for and where it is used

Glyceryl oleate is an ester of glycerin and oleic acid. It acts as an emulsifier and skin and hair conditioning agent, making it a popular ingredient in cosmetics and personal care products.

Food

Flavouring, solubilising, hydrophilic emulsifier.

Cosmetics

Antifoaming and dispersing agent. Stabilising emulsifier in oil/water formulations.

Skin conditioning agent - Emollient. Emollients have the characteristic of enhancing the skin barrier through a source of exogenous lipids that adhere to the skin, improving barrier properties by filling gaps in intercorneocyte clusters to improve hydration while protecting against inflammation. In practice, they have the ability to create a barrier that prevents transepidermal water loss. Emollients are described as degreasing or refreshing additives that improve the lipid content of the upper layers of the skin by preventing degreasing and drying of the skin. The problem with emollients is that many have a strong lipophilic character and are identified as occlusive ingredients; they are oily and fatty materials that remain on the skin surface and reduce transepidermal water loss. In cosmetics, emollients and moisturisers are often considered synonymous with humectants and occlusives.

Surfactant - Emulsifying agent. Emulsions are thermodynamically unstable and are used to soothe or soften the skin and emulsify, so they need a specific, stabilising ingredient. This ingredient forms a film, lowers the surface tension and makes two immiscible liquids miscible. A very important factor affecting the stability of the emulsion is the amount of the emulsifying agent. Emulsifiers have the property of reducing the oil/water or water/oil interfacial tension, improving the stability of the emulsion and also directly influencing the stability, sensory properties and surface tension of sunscreens by modulating the filmometric performance.

Plastic: flux dropping and anti-fog agent, lubricant and antistatic agent.

Textile: lubricant, emulsifier of industrial spinning oil.

Biodegradable and non-irritating.

This in vitro study finds that glyceryl monooleate (Glyceryl oleate) may play the role of a novel thermosensitive monoglyceride-based drug delivery system, particularly for local intracavitary chemotherapy (1).

This in vitro study evaluated the improvement of stratum corneum penetration kinetics by two common ingredients incorporated in topical skin formulations for skin protection and hydration, petrolatum and soybean oil. Glyceryl monooleate enhanced skin penetration for petrolatum (2).

Cubosomes are self-assembled liquid crystalline particles of certain surfactants and glyceryl monooleate is one of the most common surfactants used to produce cubosomes (3).

Safety

Glyceryl monooleate has been approved by the FDA (Food and Drug Administration) for food use and is considered biocompatible. It has been evaluated for genotoxicity, repeated dose toxicity, reproductive toxicity, local respiratory toxicity, phototoxicity/photoallergenicity, skin sensitisation and environmental safety. The data show that glyceryl monooleate is not genotoxic (4).

Glyceryl Oleate, Glyceryl monooleate studi

Typical optimal commercial product characteristics Glyceryl monooleate

| Appearance | Yellow to amber liquid |

| Boiling Point | 483.3±35.0 °C at 760 mmHg 409°C |

| Melting Point | 35-38ºC |

| Flash Point | 155.4±19.4 °C |

| Density | 0.9407 g/cm3 (35 ºC) |

| Acid value, mgKOH/g | 2.5 |

| Saponification value, mgKOH/g | 160~180 |

| Water content | ≤1.0 |

| Iodine value, gI2/100g ≤ | 113-123 |

| Fe, ppm ≤ | 20 |

| As, ppm ≤ | 5 |

| Heavy metals, ppm ≤ | 1 |

| PSA | 66.76000 |

| Pka | 13.16±0.20 |

| Solubility | chloroform: 50 mg/mL |

| LogP | 6.71 |

| Vapour Pressure | 0.0±2.8 mmHg at 25°C |

| Index of Refraction | 1.46384 (589.3 nm 35℃) |

| Storage | −20°C |

| Stability | Hygroscopic |

|  |

|  |

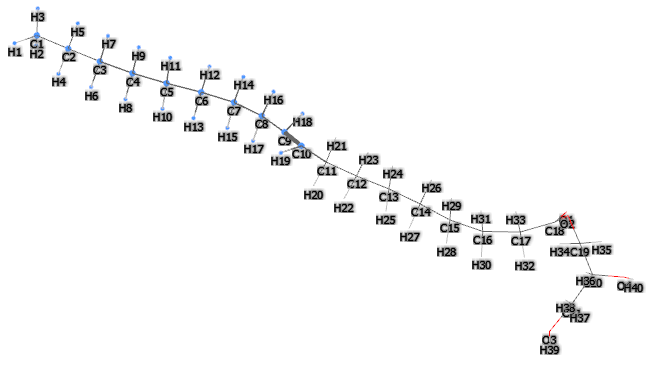

Molecular Formula : C21H40O4

- Molecular Weight : 356.5

- Exact Mass 356.292664

- CAS : 111-03-5 25496-72-4

- UNII D3AEF6S35P

- EC Number: 203-827-7 247-038-6 266-951-0

- DSSTox Substance ID: DTXSID6028319 DTXSID3027875 DTXSID3029360 DTXSID3042003

- MDL number MFCD00042735

- PubChem Substance ID 24897178

- IUPAC 2,3-dihydroxypropyl (Z)-octadec-9-enoate

- InChI=1S/C21H40O4/c1-2-3-4-5-6-7-8-9-10-11-12-13-14-15-16-17-21(24)25-19-20(23)18-22/h9-10,20,22-23H,2-8,11-19H2,1H3/b10-9-

- InChl Key RZRNAYUHWVFMIP-KTKRTIGZSA-N

- SMILES CCCCCCCCC=CCCCCCCCC(=O)OCC(CO)O

- ChEBI 75342

- FEMA 2526

- NSC 406285

- JECFA 919

Synonyms:

- Glyceryl monooleate

- 1-Oleoyl-rac-glycerol

- 1-oleoylglycerol

- Glyceryl cis-9-octadecenoate

- DL-α-Monoolein

- Monoolein

- 1-(cis-9-Octadecenoyl)-rac-glycerol, rac-Glycerol 1-monooleate

References_________________________________________________________________

(1) Mengesha AE, Wydra RJ, Hilt JZ, Bummer PM. Binary blend of glyceryl monooleate and glyceryl monostearate for magnetically induced thermo-responsive local drug delivery system. Pharm Res. 2013 Dec;30(12):3214-24. doi: 10.1007/s11095-013-1230-1.

Abstract. Purpose: To develop a novel monoglycerides-based thermal-sensitive drug delivery system, specifically for local intracavitary chemotherapy....Conclusions: The in vitro NF release profiles form the monoglycerides matrix containing 0.5% OA-Fe3O4 nanoparticles after AMF activation confirmed the thermo-responsive nature of the matrix that could provide pulsatile drug release 'on-demand'.

(2) Intarakumhaeng R, Shi Z, Wanasathop A, Stella QC, Wei KS, Styczynski PB, Li C, Smith ED, Li SK. In vitro skin penetration of petrolatum and soybean oil and effects of glyceryl monooleate. Int J Cosmet Sci. 2018 Aug;40(4):367-376. doi: 10.1111/ics.12469.

(3) Garg G, Saraf S, Saraf S. Cubosomes: an overview. Biol Pharm Bull. 2007 Feb;30(2):350-3. doi: 10.1248/bpb.30.350.

Abstract. Cubosomes are nanoparticles but instead of the solid particles, cubosomes are self-assembled liquid crystalline particles of certain surfactant with proper ratio of water with a microstructure that provides unique properties of practical interest. The discovery of cubosomes is a unique story and spans the field of food science, differential geometry, biological membranes and digestive processes. One of the most common surfactants used to make cubosomes is the monoglyceride glycerol monoolein. Bicontinuous cubic liquid crystalline phase is an optically clear, very viscous material that has a unique structure at the nanometer scale. The word bicontinuous refers to the division of the two continuous but non-intersecting aqueous regions by a lipid bilayer that is contorted into a space-filling structure. Hydrating a surfactant or polar lipid that forms cubic phase and then dispersing the solid-like phase into smaller particles usually form Cubosomes. There is a lot of excitement about the cubic phases because its unique microstructure is biologically compatible and capable of controlled release of solubilized active ingredients like drugs and proteins.

(4) Api AM, Belsito D, Biserta S, Botelho D, Bruze M, Burton GA Jr, Buschmann J, Cancellieri MA, Dagli ML, Date M, Dekant W, Deodhar C, Fryer AD, Gadhia S, Jones L, Joshi K, Kumar M, Lapczynski A, Lavelle M, Lee I, Liebler DC, Moustakas H, Na M, Penning TM, Ritacco G, Romine J, Sadekar N, Schultz TW, Selechnik D, Siddiqi F, Sipes IG, Sullivan G, Thakkar Y, Tokura Y. RIFM fragrance ingredient safety assessment, glyceryl monooleate, CAS Registry Number 111-03-5. Food Chem Toxicol. 2021 Mar;149 Suppl 1:111992. doi: 10.1016/j.fct.2021.111992.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

Read other Tiiips about this object in __Italiano (1)

Component type: Chemical Main substances: Last update: 2022-11-23 19:04:32 | Chemical Risk: |