Ultramarines is a chemical compound, a blue synthetic dye composed of complex sulfosilicates of sodium and aluminum. It is known as Pigment Violet 15, Lazurite, CI 77007.

Ultramarines is chemically classified as an inorganic colorant. It is a synthetic pigment composed of complex sodium aluminum sulfosilicates. This pigment is widely used in various industrial and cosmetic products due to its unique color properties and stability.

Chemical Composition and Structure

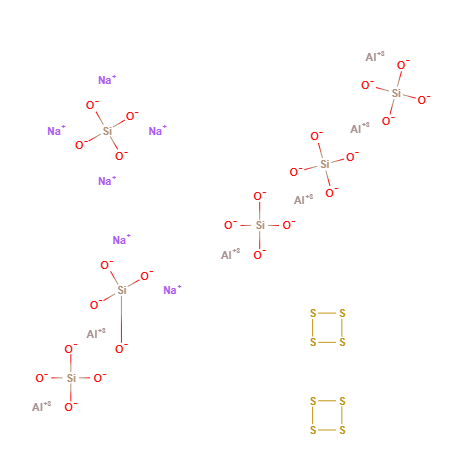

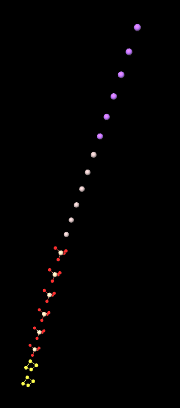

Ultramarines is an inorganic pigment with a chemical formula that can be represented as Na-Al-Si-O-S, indicating the presence of sodium, aluminum, silicon, oxygen, and sulfur in its structure. It is a complex compound formed by sodium and aluminum silicates with sulfosilicate bonds, which impart distinctive color and chemical stability to the pigment.

Physical Properties

This pigment typically appears as a fine powder with an intense blue or greenish-blue color. It has excellent resistance to light and heat, making it ideal for applications requiring color stability and durability over time. Its density varies depending on the specific composition and production process, but it is generally characterized by high opacity and covering power.

Chemical Industrial Synthesis Process

- Preparation of reagents. The main raw materials include sodium sulfate, aluminum oxide, silica, and sodium sulfide.

- Mixing of raw materials. The powders of sodium sulfate, aluminum oxide, silica, and sodium sulfide are accurately weighed and mixed to achieve a uniform composition.

- Fusion. The mixture is fused in a high-temperature furnace (over 1000°C) to allow the components to react and form the sodium aluminum sulfosilicate pigment. This fusion requires precise control of temperature and reaction time.

- Cooling. The molten material is rapidly cooled to solidify the pigment. This rapid cooling process helps achieve a homogeneous crystalline structure.

- Crushing and grinding. The solidified material is crushed and ground into a fine powder. This step may involve the use of ball mills or other grinding machinery.

- Washing. The pigment powder is washed with deionized water to remove any soluble salts and impurities.

- Drying. The washed pigment is dried at controlled temperatures to remove residual moisture and obtain a dry powder.

- Classification. The dried powder is classified to ensure a uniform particle size. This step may involve sieving or the use of air classifiers.

- Stabilization. The Ultramarines powder is stabilized to ensure its stability during transportation and storage, preventing aggregation and degradation.

- Quality control. Ultramarines undergoes rigorous quality testing to ensure it meets standards for purity, color intensity, and safety. These tests include chemical analysis, spectroscopy, and physical tests to determine particle size and rheological properties.

What it is used for and where

Restricted cosmetic ingredient as IV/120 a Relevant Item in the Annexes of the European Cosmetics Regulation 1223/2009. Substance or ingredient reported:

Cosmetics - INCI Functions

- Colorant. This ingredient has the function of colouring the solution in which it is inserted in a temporary, semi-permanent or permanent manner, either alone or in the presence of the complementary components added for colouring.

Industrial and Cosmetic Applications

Cosmetics: Ultramarines is widely used in cosmetics, including eyeshadows, eyeliners, lipsticks, and nail polishes. Its intense blue color makes it a popular pigment for creating vibrant and long-lasting shades.

Paints and Coatings: Used in paints and coatings, Ultramarines provides stable and lightfast coloration, ideal for exterior and decorative applications.

Plastics and Polymers: This pigment is employed in coloring plastics and polymers, providing uniform and stable color that resists degradation from light and heat.

Ceramics and Glass: In ceramic and glass production, Ultramarines is used to achieve intense blue colors that withstand high-temperature firing processes.

Inks: It is also used in printing inks, where color stability is essential for the quality and durability of printed products.

Safety

The presence of aluminum poses some doubts about the absence of danger of this ingredient.

My opinion. Coloring to avoid. It’s an ingredient that makes the final product more aesthetically appealing, but it could represent a potential risk with unwanted side effects especially when used continuously as it can be absorbed by the skin or mucous membranes.

The risk of cumulation of aluminium intake should be carefully considered, which cannot be excluded as this ingredient can be found both in cosmetic products and in consumer foodstuffs such as bread, various bakery products (1)

Molecular Formula Al6Na6O24S8Si6

Molecular Weight 1108.9 g/mol

CAS 12769-96-9 1302-83-6 57455-37-5

EC number 235-811-0 215-111-1

UNII 1YZ11D167R

Synonyms:

Pigment Violet 15

Lazurite

Ultramarines

CI 77007

References_________________________________________________________________________

(1) EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS); Younes M, Aggett P, Aguilar F, Crebelli R, Dusemund B, Filipič M, Frutos MJ, Galtier P, Gott D, Gundert-Remy U, Kuhnle GG, Lambré C, Leblanc JC, Lillegaard IT, Moldeus P, Mortensen A, Oskarsson A, Stankovic I, Waalkens-Berendsen I, Wright M, Di Domenico A, van Loveren H, Giarola A, Horvath Z, Lodi F, Tard A, Woutersen RA. Re-evaluation of aluminium sulphates (E 520-523) and sodium aluminium phosphate (E 541) as food additives. EFSA J. 2018 Jul 27;16(7):e05372. doi: 10.2903/j.efsa.2018.5372.

![]() Ultramarines

Ultramarines