![]() Octyldecanol

Octyldecanol

Rating : 6

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

0 pts from Al222

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.Evaluate | Where is this found? |

| "Descrizione" about Octyldecanol by Al222 (20724 pt) | 2024-May-20 14:50 |

| Read the full Tiiip | (Send your comment) |

Octyldecanol is a chemical compound, a fatty alcohol used primarily as an emollient and emulsion stabilizer in cosmetic formulations.

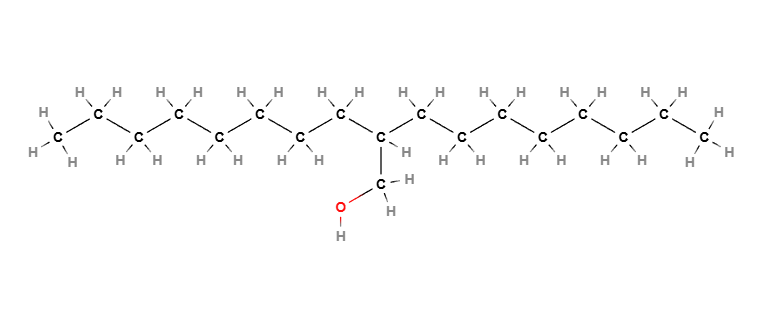

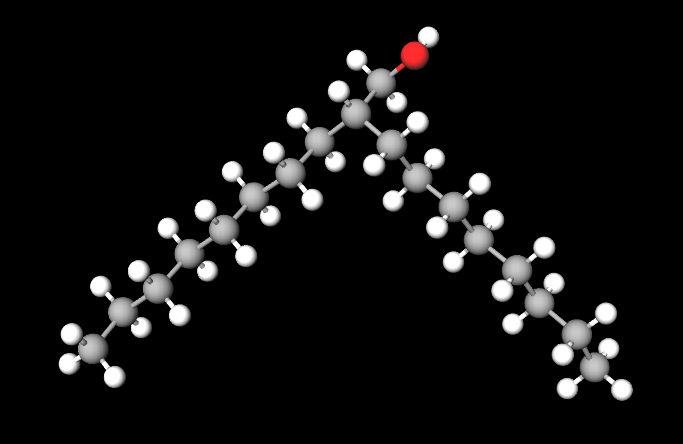

The name describes the structure of the molecule:

- Octyl is derived from the Latin word "octo," meaning eight. It indicates the presence of a chain with eight carbon atoms.

- deca is derived from the Greek word "deka," meaning ten. It indicates the presence of a chain with ten carbon atoms.

- -nol is a suffix indicating an alcohol functional group (-OH) in the chemical structure

Chemical Industrial Synthesis Process

- Preparation of reagents. The main raw materials include linear fatty alcohols, such as octyl alcohol and decyl alcohol.

- Alkylation reaction. The fatty alcohols undergo an alkylation reaction in the presence of a catalyst, such as sulfuric acid or a heterogeneous catalyst, to form octyldecanol.

- Temperature and pressure control. The alkylation reaction is conducted in a reactor at controlled temperatures and pressures to ensure efficient conversion of the reagents into octyldecanol.

- Phase separation. After the reaction, the reaction mixture is separated to remove the catalyst and other impurities through techniques such as decantation or centrifugation.

- Distillation. The mixture is then subjected to fractional distillation to isolate and purify the octyldecanol from the rest of the mixture.

- Purification. The distilled octyldecanol is further purified to remove any trace impurities using techniques such as crystallization or ultrafiltration.

- Stabilization. The purified octyldecanol is stabilized to ensure its stability during transportation and storage, preventing oxidation and degradation.

- Quality control. The octyldecanol undergoes rigorous quality testing to ensure it meets standards for purity, efficacy, and safety. These tests include chemical analysis, spectroscopy, and microbiological testing.

What it is used for and where

Octyldecanol is known for its ability to improve the texture of cosmetic products, making them creamier and softer. This fatty alcohol helps to stabilize emulsions and also acts as a skin conditioner, providing a smooth and nourishing feel. It is widely used in a variety of products, including face creams, lotions, lipsticks, and foundations, where it enhances the product's spreadability on the skin and increases the product's moisture retention capabilities.

Cosmetics - INCI Functions

- Skin conditioning agent - Emollient. Emollients have the characteristic of enhancing the skin barrier through a source of exogenous lipids that adhere to the skin, improving barrier properties by filling gaps in intercorneocyte clusters to improve hydration while protecting against inflammation. In practice, they have the ability to create a barrier that prevents transepidermal water loss. Emollients are described as degreasing or refreshing additives that improve the lipid content of the upper layers of the skin by preventing degreasing and drying of the skin. The problem with emollients is that many have a strong lipophilic character and are identified as occlusive ingredients; they are oily and fatty materials that remain on the skin surface and reduce transepidermal water loss. In cosmetics, emollients and moisturisers are often considered synonymous with humectants and occlusives.

Cosmetic Applications

Emollient Properties. Octyldecanol softens and smooths the skin, providing a feeling of softness without heaviness, making the skin more supple and reducing the feeling of dryness (1).

Thickening Effect. Helps improve the texture of cosmetic products, making them richer and creamier, which is particularly useful in creams, lotions, and conditioners.

Solubilizing. Enhances the solubilization of lipophilic ingredients, facilitating the formulation of more stable and homogeneous products.

Protective Film Formation. Creates a light film on the skin that helps retain moisture and protects the skin from external agents, keeping it hydrated (2).

Versatile Applications. Used in a wide range of products, including lipsticks, moisturizing creams, foundations, and hair care products, thanks to its compatibility with various types of formulations.

Hair Care Products. Employed in hair treatments for its conditioning capabilities, improving hair manageability and shine.

Other Applications

Pharmaceutical Industry. Used as a component in pharmaceutical preparations to improve the stability and distribution of active ingredients.

|  |

Molecular Formula C18H38O

Molecular Weight 270.5 g/mol

CAS 45235-48-1

UNII 07UG7TSU58

EC Number 917-847-5

DTXSID8068468

Synonyms:

1-Decanol, 2-octyl-

2-octyl-1-decanol

Bibliografia_____________________________________________________________________

(1) Kakubari, I., Sasaki, H., Takayasu, T., Yamauchi, H., Takayama, S., & Takayama, K. (2006). Effects of Ethylcellulose and 2-Octyldodecanol Additives on Skin Permeation and Irritation with Ethylene–Vinyl Acetate Copolymer Matrix Patches Containing Formoterol Fumarate. Biological and Pharmaceutical Bulletin, 29(8), 1717-1722.

Abstract. Emollients are one of the most commonly used ingredients in cosmetic emulsions, being closely related to the sensory properties of cosmetics and their skin sensory performance. In the present work, the sensory properties of four commonly used emollients (cyclomethicone, dimethicone, isopropyl mirystate and octyldodecanol) and four emollients from ratites oil (emú oil, ñandú oil and two products obtained by thermal fractionation of ñandú oil – estearin and olein) were characterized by means of quantitative descriptive analysis. A panel of 12 sensory assessors evaluated the following attributes: difficulty of spreading, gloss, residue, stickiness and oiliness. Considering their sensory characteristics, the evaluated emollients were sorted into five groups. By evaluating the development of residue with time after application, emollients could be regarded as dry or protective emollients, whereas considering the development of oiliness with time after application, fatty emollients were identified. PRACTICAL APPLICATIONS. The evaluated emollients showed highly significant differences in their sensory profiles, suggesting that they might provide different sensory properties to the cosmetic emulsions in which they are incorporated. Results from the present study could be used during the development of new cosmetic products, in order to select different emollients to provide different sensory characteristics to the product or while applied on the skin.

(2) Kakubari, I., Sasaki, H., Takayasu, T., Yamauchi, H., Takayama, S., & Takayama, K. (2006). Effects of Ethylcellulose and 2-Octyldodecanol Additives on Skin Permeation and Irritation with Ethylene–Vinyl Acetate Copolymer Matrix Patches Containing Formoterol Fumarate. Biological and Pharmaceutical Bulletin, 29(8), 1717-1722.

Abstract. Skin permeation of formoterol fumarate (FF) and irritation with ethylene–vinyl acetate (EVA) copolymer matrix patches was investigated using rat and human skin in vitro and different species of experimental animal, respectively. Skin permeation of FF increased remarkably without addition of ethylcellulose (EC) and was remarkably enhanced by incorporation of 2-octyldodecanol (OD) instead of hydrogenated rosin glycerol ester (Ester Gum H). Effects on skin permeation of FF with EVA matrix patches were similar in rat and human skin, but rat skin was 1000 times more permeable than human skin after 24 h. The primary irritation indices for matrix patches without EC and with EC (OD-0), EC and 0.5 mg OD per square centimeter (OD-0.5), and EC and 1.0 mg OD per square centimeter (OD-1) were 1.46, 1.13,1.29 and 1.38. The results suggested that the irritation induced by these patches was rather mild, but significantly greater than the 0.21 observed with the control. No significant effects were noted for either EC or OD alone. Skin irritation intensity with EVA matrix patches was observed to be in the order of rabbits, guinea pigs, rats and miniature swine.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

Read other Tiiips about this object in __Italiano (1)

Component type: Chemical Main substances:

Last update: 2024-05-20 14:20:30 | Chemical Risk: |